CNC Aluminum Products Machining: Precision Solutions for Your Manufacturing Needs

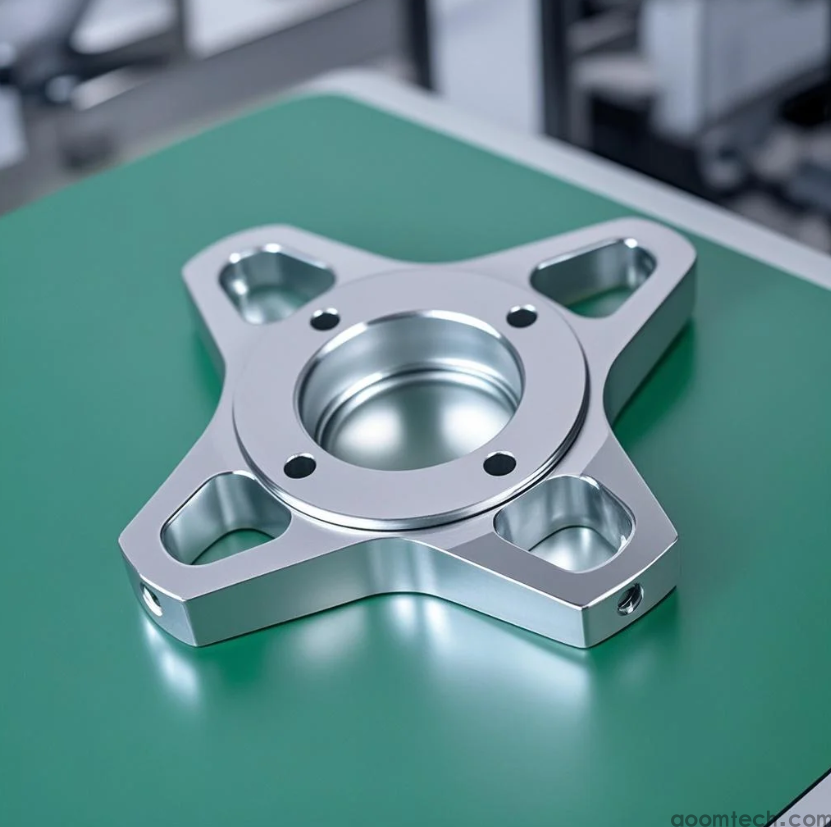

In modern manufacturing, CNC aluminum products machining plays a pivotal role in delivering high-precision components for industries ranging from aerospace to automotive. At AOOM, we specialize in advanced CNC machining techniques tailored for aluminum alloys, ensuring exceptional quality and efficiency for your projects.

Why Choose CNC Machining for Aluminum Products?

Aluminum's unique properties – lightweight, corrosion resistance, and excellent machinability – make it ideal for CNC machining. Our state-of-the-art CNC mills and lathes achieve tolerances as tight as ±.005mm, producing complex geometries with superior surface finishes. Whether you need prototypes or mass production, our process guarantees consistency across all parts.

Our CNC Aluminum Machining Capabilities

AOOM's facility features 5-axis CNC machines capable of handling aluminum alloys from 100 to 700 series. We offer:

- High-speed machining for reduced lead times

- Multi-axis simultaneous machining for complex contours

- Secondary processes including anodizing and powder coating

Quality Assurance in Every Step

Our CNC aluminum machining process includes rigorous quality checks with CMM measurement and surface roughness testing. We maintain ISO 9001 certification and provide full material traceability, ensuring your components meet the strictest industry standards.

For your next aluminum machining project, trust AOOM's expertise in CNC manufacturing. Visit aoomtech.com to request a quote or discuss your specific requirements with our engineering team.