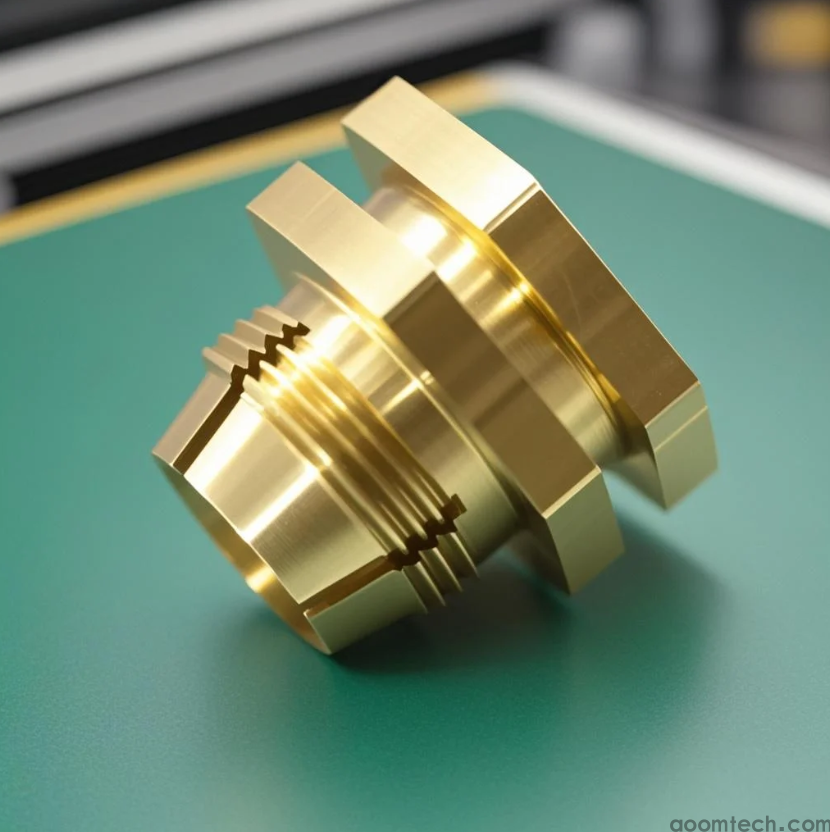

Where to Find the Best Precision CNC Machining for Brass

When it comes to precision CNC machining for brass, selecting the right manufacturer is critical for achieving high-quality, durable, and dimensionally accurate components. AOOM Technology specializes in brass CNC machining, offering advanced solutions tailored to industries like aerospace, automotive, and electronics. Here’s why our services stand out.

Why Choose AOOM for Brass CNC Machining?

Brass is a popular material due to its excellent machinability, corrosion resistance, and electrical conductivity. However, achieving precision requires expertise. At AOOM, we utilize state-of-the-art CNC machines and rigorous quality control to ensure tight tolerances (up to ±.005mm) and flawless surface finishes. Our team’s 10+ years of experience guarantees efficient production with minimal material waste.

Key Advantages of Our Brass CNC Services

Material Expertise: We work with various brass alloys (C360, C260, etc.), optimizing tool paths for each.

Advanced Equipment: Multi-axis CNC mills and lathes enable complex geometries.

Quality Assurance: ISO 9001-certified processes with 100% inspection for critical dimensions.

Applications of Precision Brass Components

From electrical connectors to marine fittings, our machined brass parts meet diverse needs. Industries rely on AOOM for:

Plumbing fixtures with leak-proof threading

High-conductivity terminals for electronics

Custom decorative hardware with mirror finishes

Partner with AOOM Technology for reliable brass CNC machining. Visit aoomtech.com to request a quote or discuss your project with our engineers today.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C