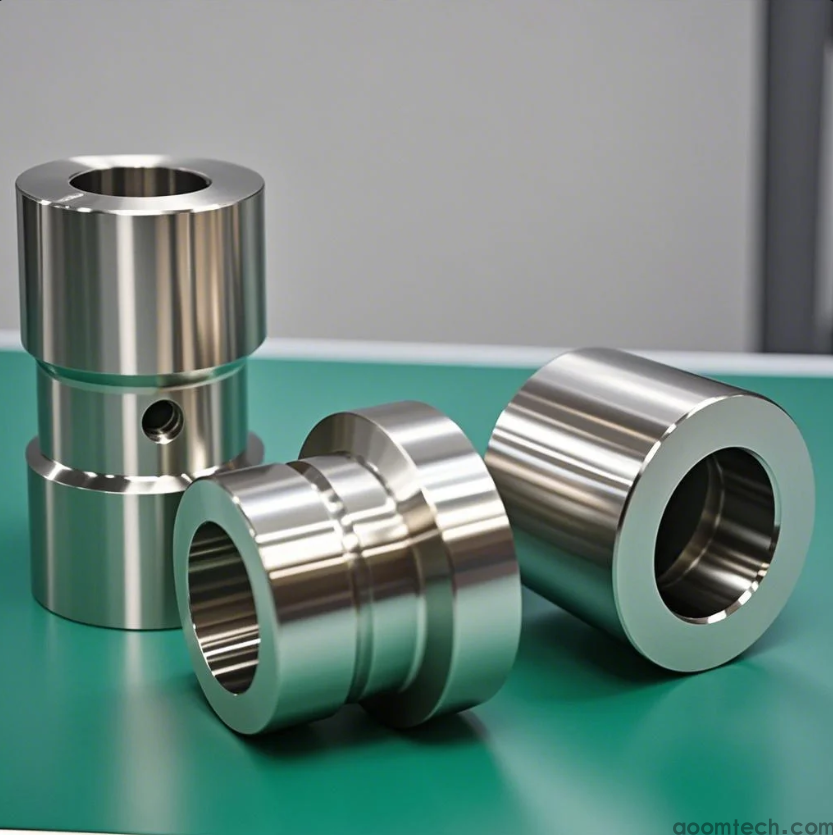

CNC Stainless Steel Custom Machining: Precision Solutions for Your Projects

In today's demanding industrial landscape, CNC stainless steel custom machining has become a cornerstone for manufacturers requiring durable, high-precision components. As a leading CNC machining service provider, AOOM Technology specializes in delivering tailored solutions that meet the strictest tolerances and surface finish requirements.

Why Choose CNC Machining for Stainless Steel?

Stainless steel's exceptional corrosion resistance and mechanical properties make it ideal for aerospace, medical, and automotive applications. Our CNC stainless steel custom machining services leverage advanced 5-axis milling and turning centers to produce complex geometries with micron-level accuracy. The process begins with material selection (304, 316, or 17-4PH grades) and progresses through CAD/CAM programming to final quality inspection.

Key Advantages of Our Custom Machining Services

1. Precision Engineering: ±.005mm tolerance capability for critical dimensions

2. Surface Finish Options: From Ra .8μm mirror finishes to textured surfaces

3. Prototype to Production: Scalable solutions with fast turnaround times

4. Material Expertise: Machining all stainless steel grades without work hardening

Applications Across Industries

Our CNC stainless steel custom machining capabilities serve diverse sectors:

- Medical: Surgical instruments and implant components

- Food Processing: Hygienic fittings and machinery parts

- Energy: Valve bodies and pump components

- Automotive: Fuel system parts and turbocharger housings

At AOOM Technology, we combine German-engineered CNC equipment with ISO 9001-certified processes to deliver stainless steel parts that exceed industry standards. Our engineering team works closely with clients to optimize designs for manufacturability and cost-efficiency without compromising quality.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C