CNC Cast Iron Machining Process Flow

Understanding CNC Cast Iron Machining

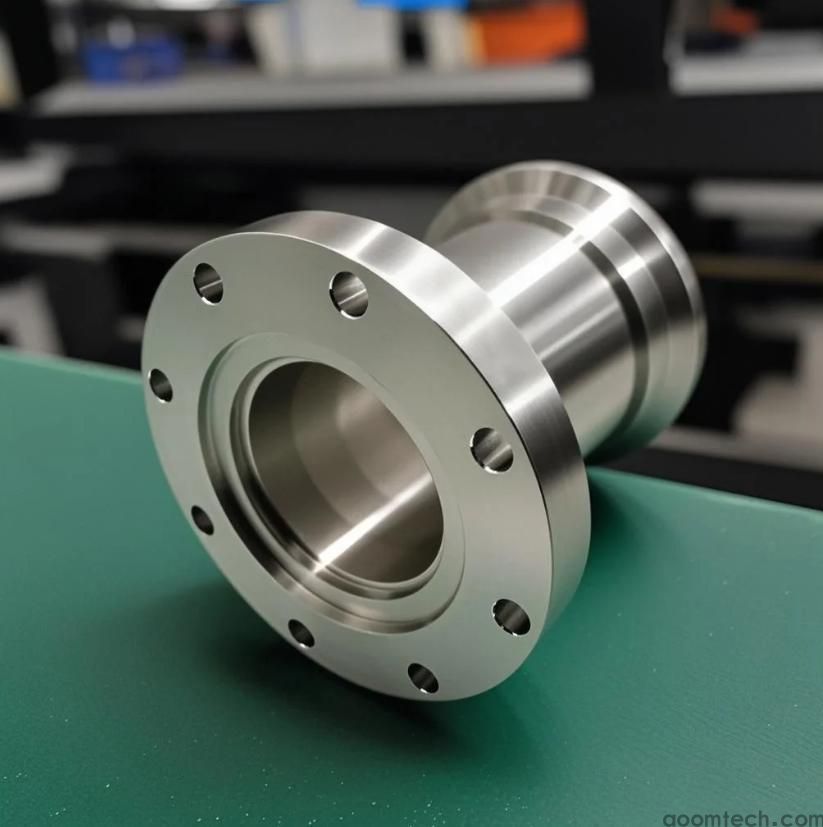

CNC cast iron machining is a specialized manufacturing process that requires precise control and expertise. As a high-strength, wear-resistant material, cast iron presents unique challenges and opportunities in CNC machining. At AOOM Technologies, we've perfected the process to deliver exceptional results for industries ranging from automotive to heavy machinery.

Key Steps in the CNC Cast Iron Machining Process

The complete CNC machining process for cast iron involves several critical stages:

1. Material Selection: Choosing the right grade of cast iron (gray, ductile, or malleable) based on application requirements.

2. Workpiece Preparation: Proper fixturing and alignment to ensure stability during machining.

3. Tool Selection: Using carbide or CBN tools specifically designed for cast iron's abrasive nature.

4. Machining Parameters: Optimizing cutting speeds, feed rates, and depth of cut to prevent tool wear.

5. Coolant Application: Implementing appropriate cooling strategies to manage heat and extend tool life.

Technical Considerations for Optimal Results

Successful cast iron CNC machining requires attention to several technical factors:

- Vibration Control: Cast iron's damping properties help, but proper machine rigidity is still essential.

- Chip Management: Cast iron produces short, brittle chips that require efficient removal systems.

- Surface Finish: Achieving desired surface quality through proper tool path strategies.

- Dimensional Accuracy: Accounting for potential material movement during machining.

Why Choose AOOM Technologies for Your CNC Cast Iron Projects

Our expertise in CNC cast iron machining sets us apart:

- Advanced Equipment: State-of-the-art CNC machines capable of handling cast iron's demands.

- Process Optimization: Years of experience fine-tuning parameters for different cast iron grades.

- Quality Assurance: Rigorous inspection protocols to ensure every part meets specifications.

- Turnkey Solutions: From design assistance to final finishing, we handle all aspects of production.

For your next cast iron machining project, trust AOOM Technologies to deliver precision, reliability, and exceptional value. Visit our website at https://www.aoomtech.com/ to learn more about our capabilities.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C