CNC Mold Machining: How to Choose the Right Supplier

Selecting the right partner for CNC mold machining is critical for manufacturing precision components. As a leading CNC machining specialist, AOOM Technology provides expert insights to help you make informed decisions.

Key Considerations for CNC Mold Machining

When evaluating suppliers for CNC mold machining, consider these essential factors:

Machining precision (typically ±.01mm for mold applications)

Material capabilities (aluminum, steel, copper alloys, etc.)

Surface finish requirements (Ra .8μm or better for mold surfaces)

Production capacity and lead times

Why Choose AOOM for Your Mold Machining Needs

AOOM Technology stands out in the CNC mold machining industry with:

15+ years of specialized mold manufacturing experience

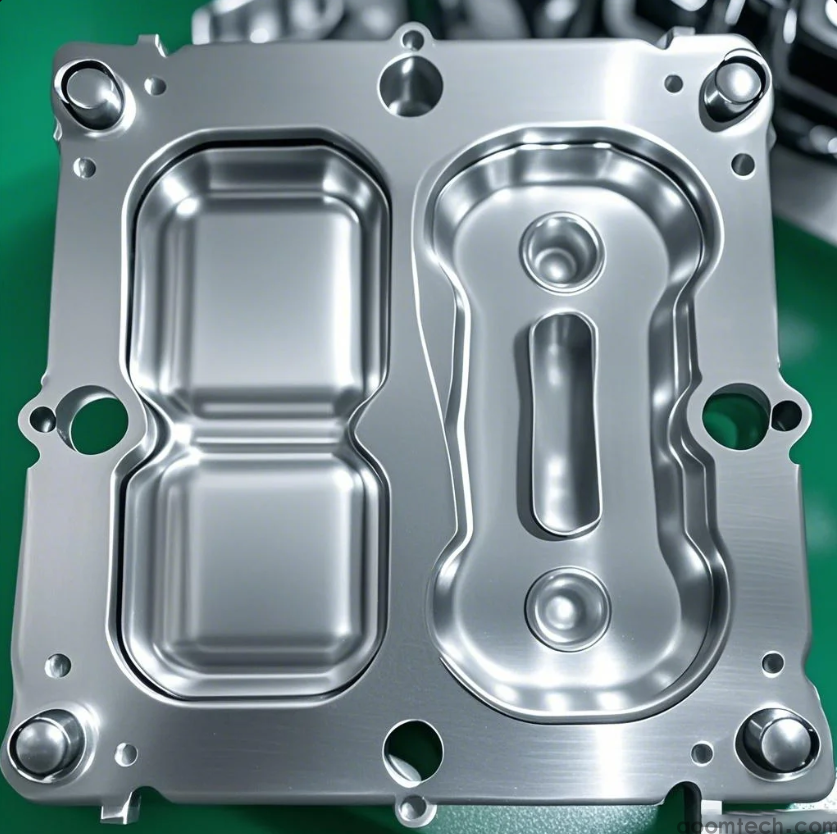

Advanced 5-axis CNC machines for complex geometries

Strict quality control with CMM inspection

Competitive pricing with fast turnaround (3-5 days for prototypes)

Technical Capabilities for Mold Production

Our facility features:

High-speed machining centers (30,000 RPM spindles)

EDM and wire-cutting for intricate details

Full-service polishing and texturing

Mold flow analysis support

For reliable CNC mold machining solutions, visit AOOM Technology or contact our engineering team for project consultation.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C