CNC Turn-Mill Combined Machining: An Efficient and Precise Tool for Modern Manufacturing

Have you ever wondered why so many factories are now using CNC turn-mill combined machining? 🤔 What makes it so indispensable for high-precision industries like aerospace, automotive, and medical manufacturing? Today, let’s take a deep dive into all things related to this technology!

🔥〖Advantages of CNC Turn-Mill Combined Machining〗

The advantages of turn-mill combined machining are truly countless! Here are the most prominent ones in my view:

- One-time clamping, full completion: No need to repeatedly handle the workpiece, which reduces errors from repeated positioning—naturally boosting precision!

- Shortened production chain: Fewer manufacturing processes mean a significant leap in production efficiency. It also saves costs on equipment floor space and fixtures!

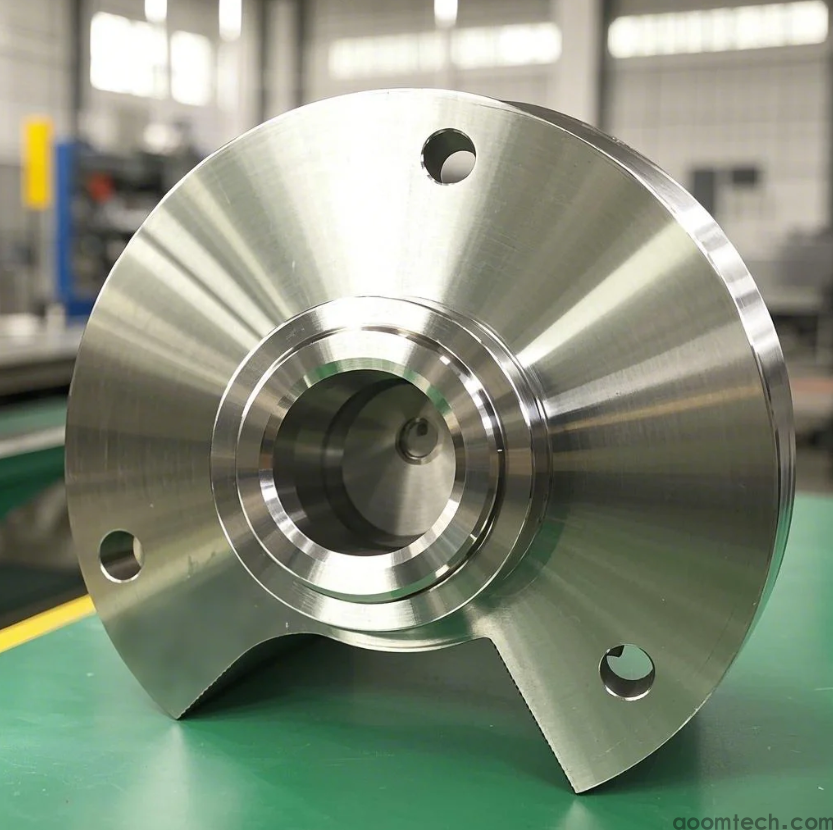

- Ideal for complex parts: It can easily handle intricate components like aerospace engine blades and precision medical parts.

🎯〖Precision of CNC Turn-Mill Combined Machining〗

Precision is where turn-mill combined machining truly excels! By reducing the number of clamping operations, it avoids error accumulation caused by datum conversion. Many machines even come with in-process inspection functions, allowing real-time monitoring of key data during machining to ensure top-tier product precision. So, for parts with extremely high precision requirements, this technology is a no-brainer!

🛠️〖CNC Turn-Mill Combined Machining Equipment〗

Turn-mill combined equipment is like a "fusion" of a CNC lathe and a machining center! It typically has five axes (X, Y, Z, A, C) and supports multi-axis linkage, making it capable of tackling challenges like 3D curved surface machining and irregular part processing. While the initial cost of the equipment is relatively high, in the long run, it saves investment and maintenance costs for multiple machines—offering great cost-effectiveness!

🌍〖Applications of CNC Turn-Mill Combined Machining〗

Its application range is incredibly wide! Let me give you a few examples:

- Aerospace: It efficiently machines complex components such as engine parts and turbine blades.

- Automotive manufacturing: It produces engine blocks, drive shafts, gears, and more—quickly and with high quality.

- Medical devices: It is indispensable for manufacturing high-precision products like surgical instruments and implants.

Basically, for any part that is complex, requires high precision, or involves multiple processes, turn-mill combined machining can shine!

💡〖CNC Turn-Mill Combined Machining Programming Tips〗

Programming is the key to unlocking the full potential of turn-mill combined machining. It requires mastery of both turning and milling programming techniques. From my experience, to excel at it, you should pay attention to these points:

- Reasonable process planning: Arrange the machining sequence properly to ensure all processes are completed efficiently in one clamping.

- Make good use of CAM software: Advanced CAM software helps handle multi-axis linkage paths, making programming more intuitive.

- Never skip simulation verification: For complex parts, run a simulation before machining to avoid tool collisions or over-cutting!

🧐 Personal Insights – A Final Note from Me

While turn-mill combined machining is indeed impressive, it’s not a one-size-fits-all solution. In my opinion, for simple parts, traditional single-function machines may be more economical. However, for complex, high-value parts, turn-mill combined machining can fully leverage its advantages. Although the initial investment is substantial, it’s well worth it in the long run! The key is to choose based on the specific characteristics of your products. I hope this sharing helps you!

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C