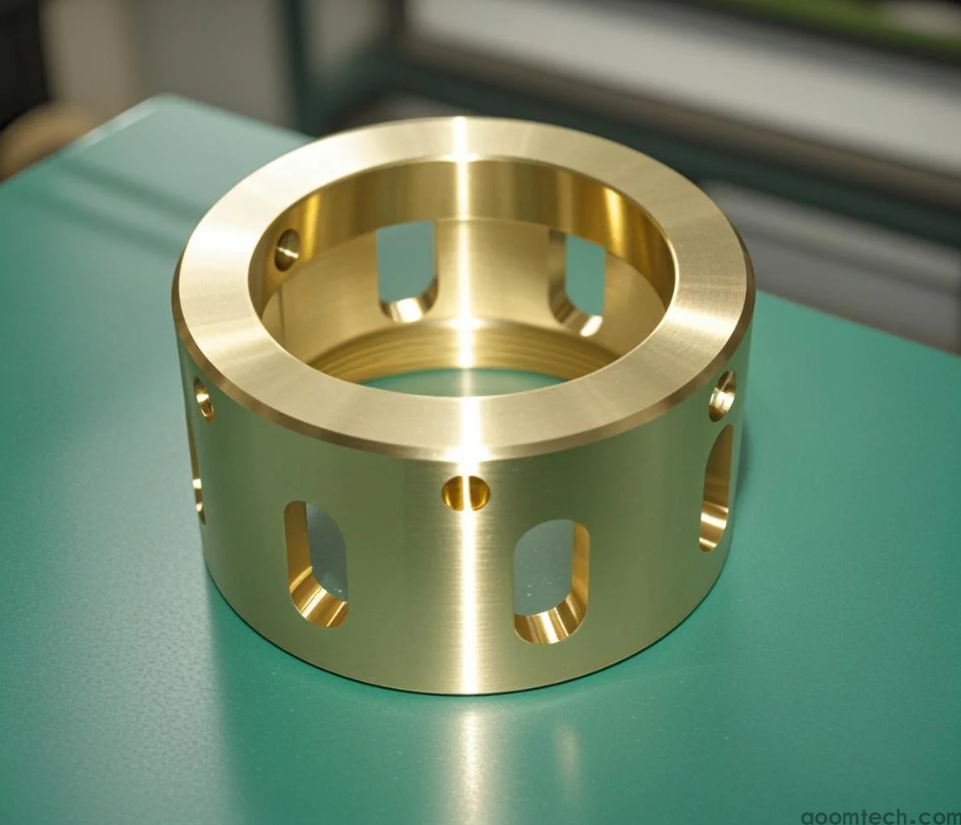

Guide to Selecting CNC Precision Machining Manufacturers for Copper Parts and Price Analysis

〖CNC Precision Machining Manufacturers for Copper Parts〗

To be honest, you can’t just judge a manufacturer by its scale! After visiting over a dozen factories, I found that small workshops often pass off used equipment as new, while large factories are too swamped with orders to pay attention to small clients… Actually, the core of choosing a factory lies in equipment transparency and real photos of case studies! For example, manufacturers that dare to disclose precision data (such as ±0.01mm) and provide real photos of customer cases are 80% reliable 👍.

〖CNC Machining Factories for Precision Copper Parts〗

What’s the key to precision machining? Material grades and testing equipment are critical!

- Don’t only focus on brass H59. H62 has higher hardness and is suitable for wear-resistant parts, but it costs 10% more!

- Factories must be equipped with coordinate measuring machines (with a precision of 0.001mm) and roundness testers — any factory without these devices is simply misleading you.

My view: Factories that dare to sign quality agreements are more reliable than those that only boast about their scale — for instance, committing to “free rework if the defect rate exceeds 5%” and putting it in black and white!

〖CNC Precision Machining of Brass Parts〗

Is brass machining prone to problems? I’ve learned this the hard way —

- Fast tool wear: Brass tends to stick to tools, so tungsten steel coated tools are a must. Otherwise, the dimensional deviation can be as large as 0.1mm!

- Easy surface scratches: Special fixtures are required for precision machining; otherwise, the polished surface will be covered in clamp marks 💔.

✅ Reliable factories conduct salt spray tests (96 hours without rust is considered qualified), and the thickness of the anti-oxidation electroplating layer is at least 5μm!

〖CNC Machining of High-Precision Copper Parts〗

“High precision” isn’t just empty talk! It depends on these hard indicators:

- Tolerance ≤ 0.015mm (1/5 the diameter of a human hair) and surface roughness Ra ≤ 0.8μm;

- Equipment brands: Japanese Star Swiss-type lathes and German Siemens control systems — no off-brand equipment can meet these standards!

👉 My pro tip: Ask the manufacturer to send real-time machining videos, and focus on whether the spindle speed is stable (immediately reject factories with a speed fluctuation exceeding 5%).

〖Small-Batch CNC Precision Machining of Copper Parts〗

Large factories don’t like taking small-batch orders? Then focus on manufacturers that specialize in small-batch production! Their advantages are obvious:

- Fast response: Prototyping takes 1–5 days, while large factories require a 2-week wait at minimum;

- Lower costs: No brand premium, so the same brass parts are 15%–20% cheaper than those from large factories;

- High flexibility: Support customization based on drawings, and even help you optimize designs to avoid pitfalls!

My personal test: A small factory in Dongguan uses Japanese Tsugami equipment to produce medical copper parts, and its salt spray test showed no rust for 96 hours — even better than some well-known large factories.

Price Traps: Low Quotes Aren’t Necessarily Good!

“CNC machining of copper parts for 0.5 yuan/piece” — never believe such offers! I’ve broken down the costs:

- Materials account for 60% (using inferior copper to pass off as H59);

- Process cuts (omitting polishing/electroplating);

- Replacing 100% inspection with sampling inspection (defect rate soars to 30%!).

✅ Real Price Range (Market Reference):

| Machining Type | Reasonable Unit Price | Trap Warning |

|----------------------|-----------------------|---------------------------------------|

| Brass Part Milling | 10–18 RMB/piece | Prices below 10 RMB may skip inspection |

| High-Precision Turning | 25–50 RMB/piece | Be cautious if no equipment model is specified |

| Small-Batch Complex Parts | 80–150 RMB/piece | Avoid factories that don’t mention material certificates |

My final note: When looking for CNC manufacturers for copper parts, don’t blindly chase “big brands.” Focus on factories that dare to show their equipment, share case studies, and sign quality agreements — they often bring you surprises. After all, their reputation is truly built piece by piece with quality parts 🔥!

Would you like me to organize a bilingual glossary of core terms for copper part CNC machining? It will include Chinese terms, their English translations, and explanations of key parameters (such as material grades and precision indicators) to help you communicate accurately with overseas manufacturers.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C