CNC Processing Factory Selection_Tips for Aluminum Alloy Part Machining

Hello everyone, I’m Brother Yun, the editor, who has focused on the mechanical manufacturing field for 10 years! Today, let’s talk about topics like "CNC Processing Factory Selection_Tips for Aluminum Alloy Part Machining". Many newbies who have just entered this industry always struggle with how to find reliable factories, or what to pay attention to when machining aluminum alloys. Don’t worry, combining practical experience, I’ll break it down for you in plain language!

🔍 1. What is CNC Machining? Why is it Important?

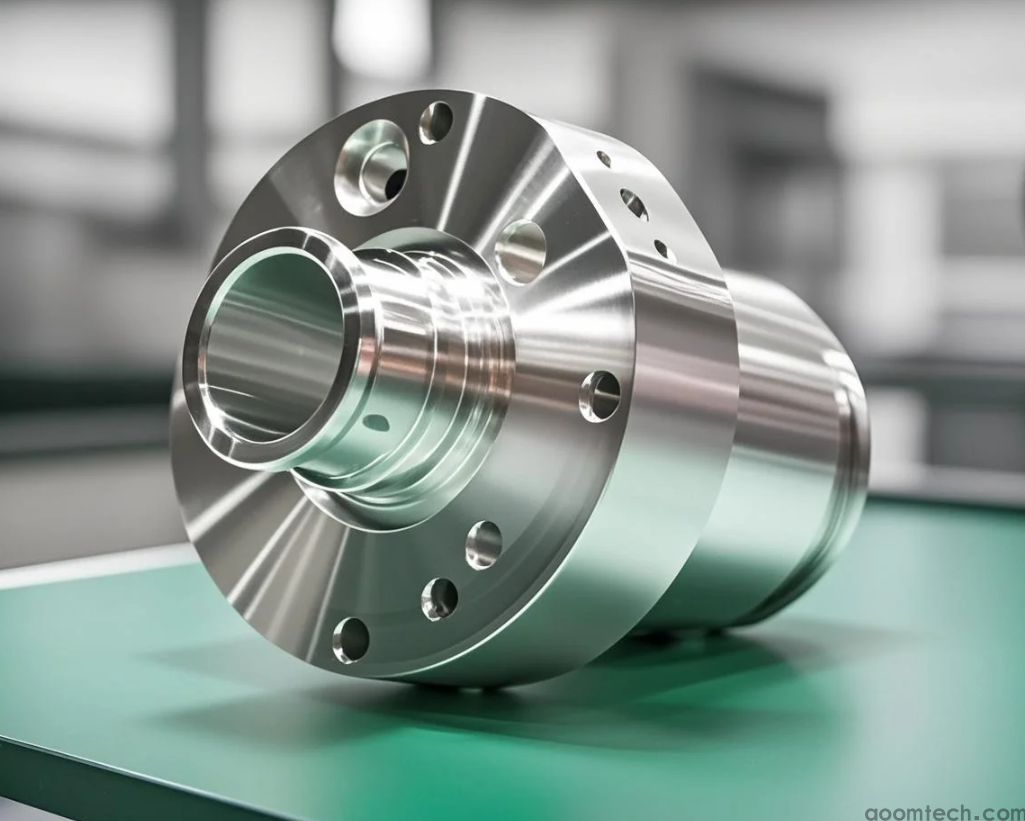

CNC (Computer Numerical Control) machining is essentially a process where computers control machine tools to cut and carve parts. For example, many items like the metal frames of your mobile phones, automotive engine blades, and even medical scalpels are made through CNC machining! Its advantages are extremely obvious:

- High precision: The error can be controlled within 0.01mm, which is thinner than a human hair!

- High efficiency: With automated production, there’s no need to worry about batch orders.

- Capable of handling complex shapes: For instance, curved surfaces like those of aircraft turbine blades can’t be processed by ordinary machine tools at all.

However, it should be noted that not all parts require 5-axis CNC machines. For simple flat surfaces, 3-axis machines are sufficient; otherwise, it would be a case of overkill.

🤔 2. How to Choose the Right CNC Processing Factory? A Must-Read for Newbies!

Many friends ask, "Editor, there are so many factories, which aspects should I focus on?" Actually, the key lies in these 4 points:

1. Advanced equipment: 5-axis machine tools are suitable for complex curved surfaces (such as aerospace parts), while turn-mill composite machines can finish multi-surface machining in one go, saving time and effort.

2. Material experience: The machining difficulty varies among aluminum alloys, stainless steels, and titanium alloys! Some factories specialize in aluminum parts (e.g., those manufacturing auto parts), so don’t choose the wrong type of factory.

3. Quality inspection capability: Reliable factories will use 2.5D measuring instruments – they rely on data and reject defective products.

4. Acceptance of small orders: New businesses often need small-batch trial production. Ask in advance about the minimum order quantity to avoid hold-ups.

My suggestion: Prioritize factories with cases in the medical or automotive industries, as these industries have stricter standards and more stable quality!

⚙️ 3. Aluminum Alloy Machining Secrets: Save Money and Avoid Troubles

Aluminum alloy is a popular material in CNC machining due to its light weight and corrosion resistance! But newbies often encounter problems – for example, improper design can double the cost 😤. These tips will help you avoid pitfalls:

- Avoid deep cavities in design: If the tool can’t reach the deep areas, special tools have to be used, which increases costs!

- Use rounded corners instead of sharp corners for internal angles: Milling cutters naturally move along curves, while right angles are more difficult to machine.

- Don’t make the wall thickness too thin: Thin walls are prone to vibration and deformation, leading to precision failure! It’s recommended that the thickness be more than 3mm.

By the way, surface treatment is also important! Anodizing can add color and increase hardness, making it suitable for electronic products; sandblasting, on the other hand, makes the surface more wear-resistant, which is ideal for mechanical parts.

📊 4. Price Comparison: How to Inquiry Without Losing Out

| Machining Type | Typical Quotation (RMB/piece) | Suitable Scenarios |

|------------------------------|--------------------------------|----------------------------------|

| Small-batch Aluminum Alloy | 50 - 200 | Prototype trial production |

| Precision Stainless Steel | 200 - 500 | Medical device parts |

| 5-axis Complex Curved Surfaces| 800 - 2000 | Aerospace components |

Data source: Industry research + public quotations from Factory C

⚠️ Note: Prices fluctuate greatly! For example, due to the high hardness of titanium alloy, tool wear is significant, which directly doubles the cost. Therefore, when sending drawings for quotation, be sure to specify the material, precision, and quantity – don’t be shocked when you receive the quotation!

💡 5. My Opinion: Future Trends and Advice for Newbies

Some people say, "AI will soon replace factories, so why learn about CNC?" That’s nonsense! High-end manufacturing will always be short of talents – especially compound talents who understand both design and machinery. My predictions are as follows:

- Lightweight materials (such as carbon fiber-aluminum alloy composites) will become popular, and the automotive and UAV industries are in urgent need of them!

- Software skills will be more important: CAD/CAM programming is the core. Without software knowledge, even operating machine tools is useless.

For newbies starting out, it’s recommended to first become proficient in machining simple materials (like aluminum parts) before moving on to more challenging ones like stainless steel! Cooperating with a reliable factory for trial orders is much better than just reading books blindly~

Finally, here’s a solid piece of data: The precision machining market grew by 30% in 2025, but 80% of new factories failed in the quality inspection stage. Therefore, quality is more important than anything else! I hope this article can help you. If you have any questions, leave a comment below, and I’ll reply online~

Would you like me to sort out a bilingual comparison table of common aluminum alloy grades for CNC machining? It will include Chinese and English names of grades, mechanical properties, and suitable application scenarios, helping you quickly select the right material when communicating with overseas factories.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C