How to Measure CNC Machining Accuracy_Methods for Accurate CNC Machining Quotations

I’m often asked questions like, “How exactly do you measure CNC machining accuracy?” and “Is there a reliable way to get quotations?” 😅 Especially newbies, who don’t understand industry jargon at all—they’re afraid of being scammed and also worried about miscommunication. Having worked in the manufacturing industry for 10 years, I’ll break down these two questions in plain language today to help you avoid common pitfalls!

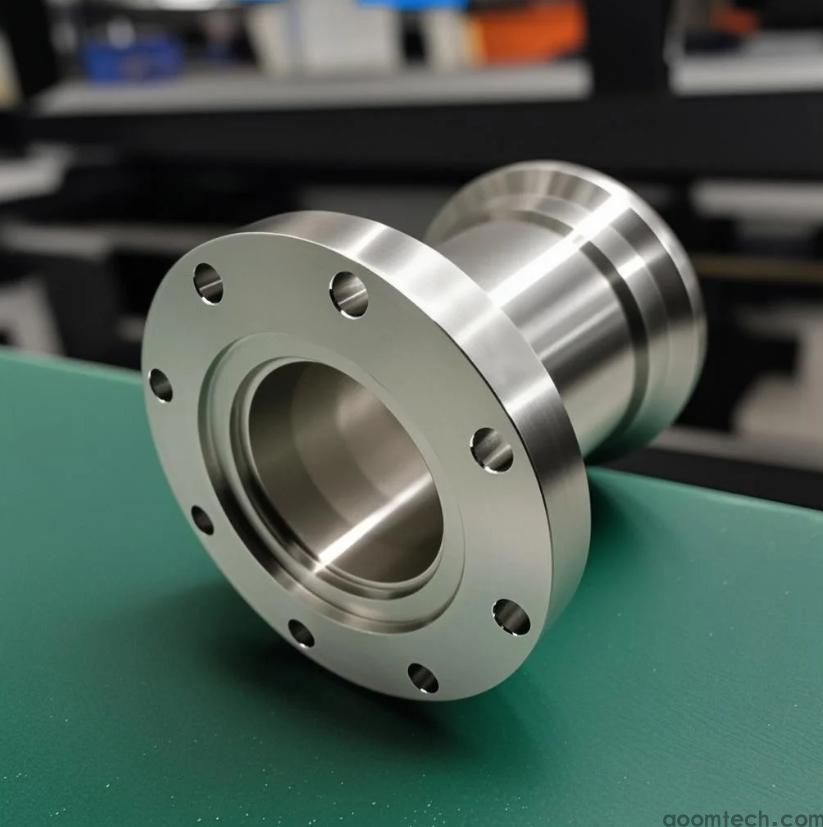

🔍 1. CNC Accuracy: From “Approximate” to “Micron-Level” Precision

The “accuracy” of CNC machining isn’t based on feeling! It relies on micron-level precision—1 micron is equivalent to 1/60 the diameter of a human hair! 🤯 For example, aerospace parts may require a tolerance of ±0.005mm, while ordinary hardware parts may only need ±0.05mm.

💡 How to Determine if Accuracy Meets Standards?

- Check the tolerance grade: For instance, “IT7 grade” has higher accuracy than “IT10 grade”;

- Measuring tools: Coordinate Measuring Machines (CMM) and optical scanners are common testing equipment;

- Process impact: 5-axis machine tools are usually more suitable for complex curved surfaces than 3-axis ones, with lower errors.

My view: Higher accuracy isn’t always better! Pursuing excessive micron-level precision may double the cost 💸. First, clarify the product’s purpose—for example, the accuracy requirements for a phone case and a rocket engine are completely different. Don’t pay for “excessive accuracy”!

📊 2. The “Hidden Logic” Behind CNC Quotations

Many people are confused when they receive a quotation: “Why is there such a big price difference between different manufacturers for the same size?” 😵 In fact, quotations depend on four key factors:

1. Material Cost

- Metals: Aluminum alloy < Stainless steel < Titanium alloy;

- Plastics: ABS < Nylon < PEEK (special for medical grade);

2. Working Hours and Equipment

- High-speed machine tools: Reduce working hours but have a higher unit price;

- Multi-axis equipment: 5-axis machining for complex parts costs more, but it can reduce secondary clamping errors;

3. Post-Processing Requirements

- Additional processes like anodizing, electroplating, and laser engraving are charged item by item;

4. Order Quantity

- Small-batch orders have a higher unit price, while large-batch orders usually spread out costs.

✅ Reference for a Simple Quotation Formula:

Total Price = (Material Cost + Hourly Rate × Processing Time) × Quantity + Post-Processing Fees

(Note: The hourly rate varies by equipment grade. Ordinary 3-axis machine tools cost approximately 80-120 RMB/hour, while 5-axis ones may cost 200-300 RMB/hour)

❓ 3. Q&A: 2 Core Questions Newbies Must Know

Q1: “How do I know if the accuracy the manufacturer claims is real?”

- Request test reports (such as data on hole diameter and roundness);

- First do a small-batch sample verification and self-inspect with a 2D measuring instrument;

- Choose factories certified with IATF16949/ISO9001 (quality system guarantee).

Q2: “Why are some manufacturers’ quotations particularly low?”

- They may use used tools or old equipment, leading to poor accuracy stability;

- Omit necessary testing steps, resulting in high risks of returns later;

- Use inferior materials to replace high-quality ones (e.g., using unbranded aluminum instead of 6061 aerospace aluminum).

My reminder: Be alert if a quotation is more than 20% lower than the market price! Choosing cheap options may result in getting useless defective parts, and delays in delivery will cause even greater losses 😭.

🛠️ 4. Practical Advice for Newbies: How to Choose the Right Supplier?

1. Check the equipment list: Prioritize manufacturers with 5-axis machine tools and high-speed machines (strong ability to handle complex parts);

2. Ask for real cases: Let the manufacturer provide photos, videos, or samples of similar products they’ve made before;

3. Clarify acceptance criteria: Clearly state the tolerance range, testing methods, and handling methods for unqualified products in the contract;

4. Place a small-batch trial order: First order 5-10 pieces to inspect the quality, then scale up the order.

Finally, I want to say that CNC machining is a technical job, but it’s not that mysterious. The balance between accuracy and price is the wise choice in the manufacturing industry! I hope you’ll feel confident when placing orders next time and avoid falling into pitfalls~👍

Would you like me to organize a bilingual glossary of CNC machining accuracy and quotation terms? It will include Chinese terms, their English translations, and detailed explanations, making it easier for you to communicate with overseas suppliers about accuracy requirements and quotation details.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C