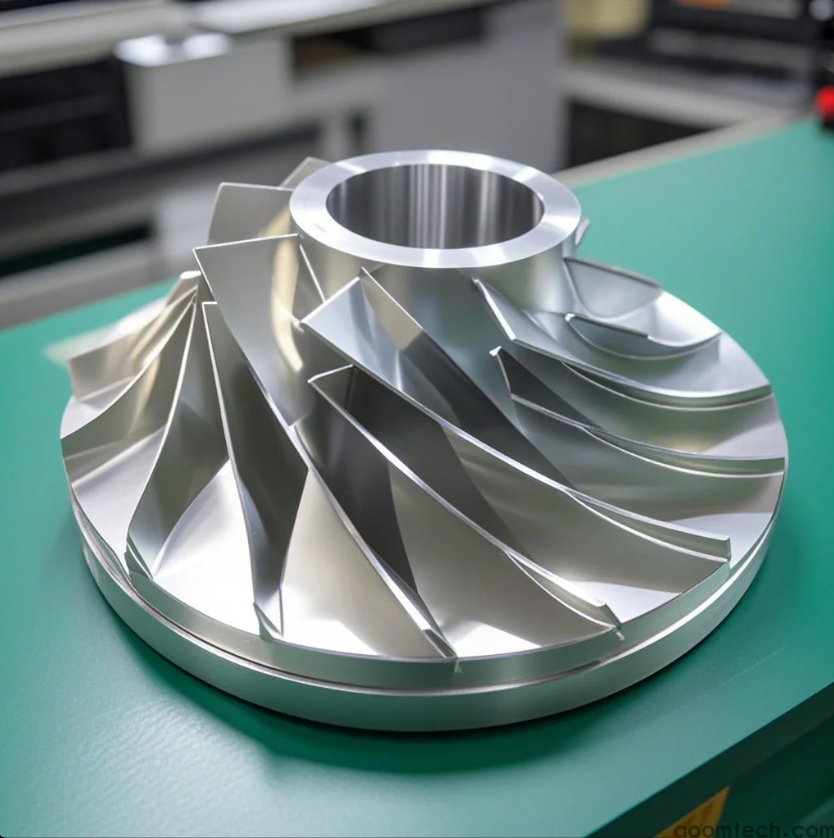

Custom Non-Standard Parts Machining _ Aluminum Alloy CNC Machining

Are you new to CNC machining and feel overwhelmed when hearing terms like "custom non-standard parts" or "aluminum alloy machining"? Don’t panic! I’ll break it down for you in plain language — it’s actually not that complicated! 👉

❶ Custom Non-Standard Parts Machining: What Exactly Is It?

"Non-standard" simply means "non-standard parts" 🧩, which need to be customized according to your drawings! For example:

- Special gears and irregular connectors

- Unusual small parts used in equipment modification

- Prototyping for handboard models

Why is it difficult? Because there are no ready-made tool paths, and programming has to start from scratch! My suggestion: Before mass production, first do a test cut of 3-5 pieces. Confirm the dimensions before proceeding with mass production; otherwise, it’s easy to make mistakes and waste materials~

❷ Aluminum Alloy CNC Machining: Why Is It the Most Popular?

Aluminum is soft, lightweight, and easy to cut! However — different grades of aluminum have vastly different properties:

- 6061: Commonly used, easy to machine, with medium strength

- 7075: Aerospace-grade, hard but brittle, which causes rapid tool wear

- 5052: Corrosion-resistant, suitable for housing parts

💡 Tip: For finishing, increase the spindle speed and use a low feed rate — this will directly improve the surface finish by one level!

❸ How to Choose Tools? Aluminum vs. Steel vs. Non-Standard Materials

When machining non-standard parts, you may encounter mixed materials (e.g., aluminum substrates with embedded stainless steel nuts) — which means you’ll need to change tools! Common tool pairings:

- Aluminum parts: 3-flute flat-end mills + mist cooling (to prevent tool sticking)

- Steel parts: Coated cemented carbide tools + oil cooling

- Composite materials: Diamond-coated tools (to prevent edge chipping)

⚠️ Note: Avoid using overly long tool holders for non-standard irregular parts. Excessive vibration will definitely ruin the dimensional accuracy!

❹ Programming Guide to Avoid Mistakes: A Shortcut to Fewer Detours

Common mistakes beginners make:

1. Forgetting to set tool compensation — a 0.1mm undersize can lead to the scrapping of an entire batch!

2. Copying cutting parameters directly — different machines have different rigidity, so fine-tuning is necessary

3. Ignoring deformation — for thin-walled aluminum parts, rough machining and finish machining must be separated

👉 My habit: Leave a 0.2mm allowance during rough machining, then finish in one pass. It’s super reliable!

❺ Quality Inspection: How to Quickly Inspect Goods Yourself?

You can still check quality without a coordinate measuring machine (CMM):

- Calipers + feeler gauges: Inspect hole diameters/groove widths

- Surface roughness tester: A roughness value of Ra ≤ 3.2μm is considered up to standard (a common requirement)

- Thread plug gauges: Being able to screw in doesn’t equal qualification — you also need to check the tightness!

💥 Key point: The first non-standard part must undergo a full inspection, and the frequency of random inspections should be increased afterward!

❻ Personal Insight: How Should Beginners Quote for Orders?

Don’t calculate based on working hours alone! Break down the costs clearly:

- Material cost × 1.2 (including waste)

- Programming + debugging time (calculated by hourly rate)

- Tool depreciation (especially for finishing tools, amortize over 5-10 pieces at a time)

- Rush fee (charge extra for operating the machine at midnight!)

✅ Secret tip: Add a 30% risk premium for complex non-standard parts — because the probability of rework is really high!

Finally, a few extra words: Aluminum alloy machining may seem simple, but for parts requiring a high mirror finish (such as Apple accessories), you need to use diamond tools + 5-axis machines. For non-standard parts, it’s even more important to sign a sample confirmation form with the customer to avoid disputes~

If you have any specific questions, leave them in the comment section! I’ll be online to answer them! 🔥

Do you want me to sort out an Aluminum Alloy CNC Machining & Non-Standard Parts Production Glossary? It will help you quickly understand professional terms and communicate more smoothly with manufacturers or customers.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C