How to Choose a Reliable CNC Machining Parts Manufacturer: A Practical Guide

Hey there, fellow engineers and procurement managers! 👋 Are you tired of sifting through countless websites, trying to figure out which CNC machining partner you can actually trust? You're not alone. Finding a reliable shop feels like a gamble, where a wrong choice can lead to delayed projects, wasted budget, and a lot of headaches. So, how do you cut through the noise and make a smart decision? Let's break it down together.

🤔 The Core Question: What Should You REALLY Look For?

It's not just about who has the fanciest website or the lowest price. The real answer lies in a combination of factors. Think of it like hiring a new team member: you need to check their skills, experience, and see if they're a good fit for your company's culture. A reliable manufacturer is a partner, not just a vendor. You need to assess their technical capability, quality control, and communication.

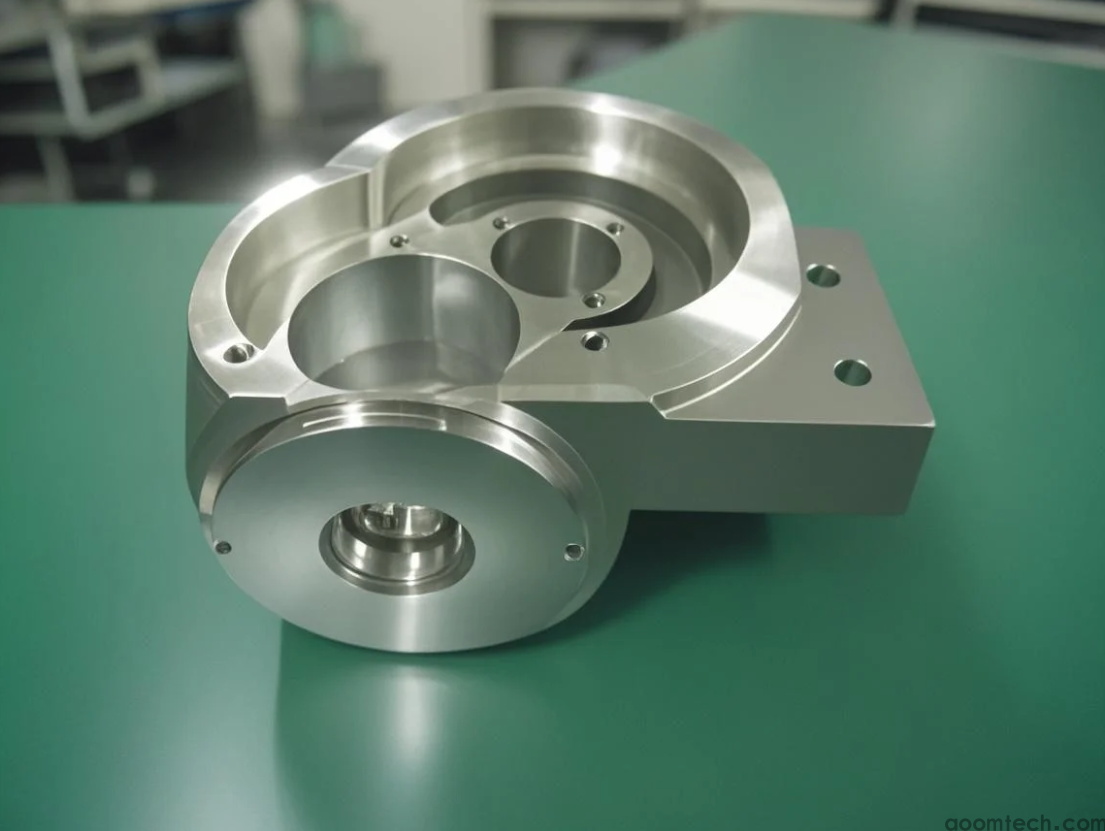

1. Dig Into Their Technical Capabilities and Equipment

Don't just take their word for it. A trustworthy shop will be proud to show off their tools.

Key things to ask:

- What types of CNC machines do they operate? (3-axis, 4-axis, 5-axis?). More axes often mean they can handle more complex parts in a single setup.

- What materials do they have experience with? From aluminum and stainless steel to engineering plastics, their expertise should match your needs.

- What is their maximum and minimum part size capacity?

My personal view: I always prefer a shop that invests in modern equipment. It often, but not always, translates to better precision and efficiency. However, an older, well-maintained machine operated by a seasoned expert can sometimes produce fantastic work. The specific interplay between machine age and operator skill is a fascinating area that deserves more attention.

2. Quality Control: It's More Than Just a Certificate

Anyone can claim they have "high quality." You need to see the proof.

Look for evidence:

- Do they have a documented quality control process? Ask about their inspection equipment (like CMMs, calipers, optical comparators).

- Can they provide First Article Inspection Reports (FAIR)? This is a huge green flag.

- Are they ISO 9001 certified? While this is a great sign of a structured system, it doesn't automatically guarantee perfect parts every time. It perhaps suggests a commitment to consistent processes.

3. Communication and Customer Service: Your Project's Lifeline

This might be the most overlooked part. A technically perfect shop is useless if you can't talk to them.

How to gauge this:

- Are they responsive to your initial inquiry? This is a preview of future communication.

- Do they ask clarifying questions about your drawings and requirements? This shows they are engaged and careful.

- Is there a dedicated point of contact for your project?

From my experience: I've walked away from shops with great prices because their communication was slow and frustrating. A partner who proactively updates you can save a project from disaster. That said, finding a shop that balances fantastic communication with top-tier technical skill can be the real challenge in this industry.

4. Don't Make Price Your Only Decision-Maker

We all have budgets to manage, but the cheapest option is often the most expensive in the long run.

Consider the total cost:

- A low price might mean corner-cutting on material quality or machining precision.

- It could also indicate a lack of proper quality control, leading to rejected parts and delays.

- Instead of just looking at the bottom line, evaluate the value. Are you getting good communication, reliable lead times, and peace of mind?

🎯 The Final Step: Start with a Small Test Project

Before you commit to a large, critical order, the best strategy is to test the waters.

Place a small, non-critical order first. This "test run" allows you to evaluate everything we've discussed in real-time: the quality of the parts, the accuracy of their quoting, their adherence to deadlines, and the smoothness of communication. It's the ultimate due diligence. This hands-on data is far more valuable than any sales pitch.

Ultimately, the right partner makes your job easier. They become an extension of your team, helping you bring your designs to life reliably and efficiently. Hope this guide helps you find yours! 🚀

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C