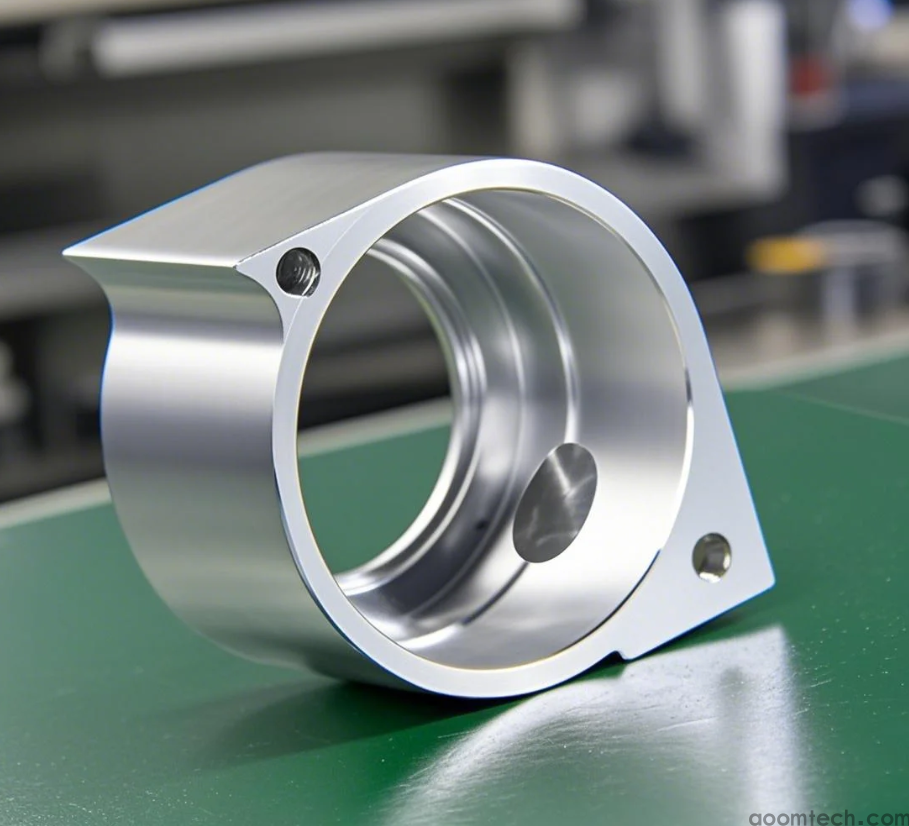

CNC Machining Seal Tolerance: Key Factors and How to Achieve Them

Hey there, fellow engineers and procurement pros! 👋 Ever found yourself staring at a technical drawing for a seal, wondering if your CNC lathe can really hit those tight tolerances? Or maybe you've received a batch of machined seals, only to find a few that just don't seal right? You're not alone. Getting the precision right is the make-or-break factor between a leak-proof masterpiece and a costly do-over. Let's break down what you actually need to know.

What Tolerance is Needed for CNC Machining Seals?

This is the million-dollar question, isn't it? The truth is, there's no single answer. It's not like baking a cake with a fixed recipe. However, for most common hydraulic and pneumatic seals, we're often talking about a tolerance in the range of ±.01 mm to ±.05 mm (±.0004" to ±.002"). For super critical applications, like in aerospace or medical devices, it can get even tighter. The real answer depends entirely on the seal's design, material, and most importantly, its function. A static seal sitting in a groove might be more forgiving than a dynamic seal rubbing against a piston all day.

It's Not Just the Machine: The Human and Material Wild Cards

We often think a fancy CNC machine guarantees perfection. I've seen shops pour money into the latest equipment but still struggle with consistency. Why? Because the machine is only one part of the puzzle.

• Operator Skill: A seasoned operator knows how to listen to the cut, adjust feeds and speeds on the fly, and spot a tool that's about to go dull. That intuition is gold.

• Material Behavior: Here's a tricky one. Some softer sealing materials can deform slightly during machining due to heat or clamping force. The part measures perfectly on the bench, but once it's free, it springs back out of spec. The specific way different polymers react to stress during cutting is a complex topic that I'm still digging into.

My Go-To Checklist for Holding Tight Tolerances

Over the years, I've developed a simple routine that rarely lets me down. It's all about controlling the variables.

1. Tooling is King: Don't run your cutting tools until they scream. I schedule tool changes proactively. A sharp tool produces less heat and gives a better surface finish, which is crucial for a good seal.

2. Master Temperature Control: The machine, the part, and the tool all generate heat. This thermal expansion can throw your dimensions off. I always let the machine warm up and use coolant effectively to keep things stable.

3. The First-Article Inspection Ritual: Never, ever skip this. The first part off the batch gets a full and thorough inspection. If it's good, you're golden. If not, you've just saved a whole batch of scrap.

When Good Tolerances Still Lead to Bad Seals

Here's a head-scratcher I encountered once: all dimensions were well within the print's tolerance, but the seals were failing pressure tests. We were baffled. It turned out the issue wasn't the diameter, but the surface finish. The microscopic grooves from the toolpath were just deep enough to create a leak path. This experience perhaps suggests that an obsessive focus on dimensional tolerance alone can sometimes blind us to other critical factors like surface integrity. So, while hitting the numbers is non-negotiable, always remember the final application. A part can be perfectly in tolerance but completely useless if it doesn't perform its job.

In my view, the real goal isn't just to machine a part to a spec on a drawing. It's to deliver a component that functions flawlessly in the real world. Sometimes that means having a conversation with the designer about whether a slightly looser tolerance on a non-critical feature could save significant cost without any performance loss. It's this kind of collaboration that separates good suppliers from great ones.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C