How to Choose a Reliable CNC Machining Service Provider: A Practical Guide

Hey there, are you a project manager or an engineer staring at a dozen quotes from different CNC shops, wondering which one won't turn your brilliant design into a costly paperweight? 🤔 You're not alone. Picking the right partner is tricky, but getting it wrong can mean delayed projects, blown budgets, and a whole lot of stress. Let's break down how to navigate this choice without the headache.

What Exactly Should You Look For First?

Before you even look at the price, you've got to check their capabilities. It's like choosing a car – you don't just buy the cheapest one without seeing if it can actually drive where you need to go!

Machine and Material Range: Do they have the right tools for your job? If you need 5-axis machining for aluminum, but their specialty is 3-axis with steel, it's a mismatch. Ask for a list of their equipment and the materials they work with regularly.

Quality Certifications: Look for signs of a serious operation. Things like an ISO 9001 certification suggest they have proper quality control processes. It's not a perfect guarantee, but it perhaps indicates they pay attention to how they work.

Why Sample Parts and Past Work Tell the Real Story

A shiny website can be deceiving. The proof is always in the parts they've actually produced.

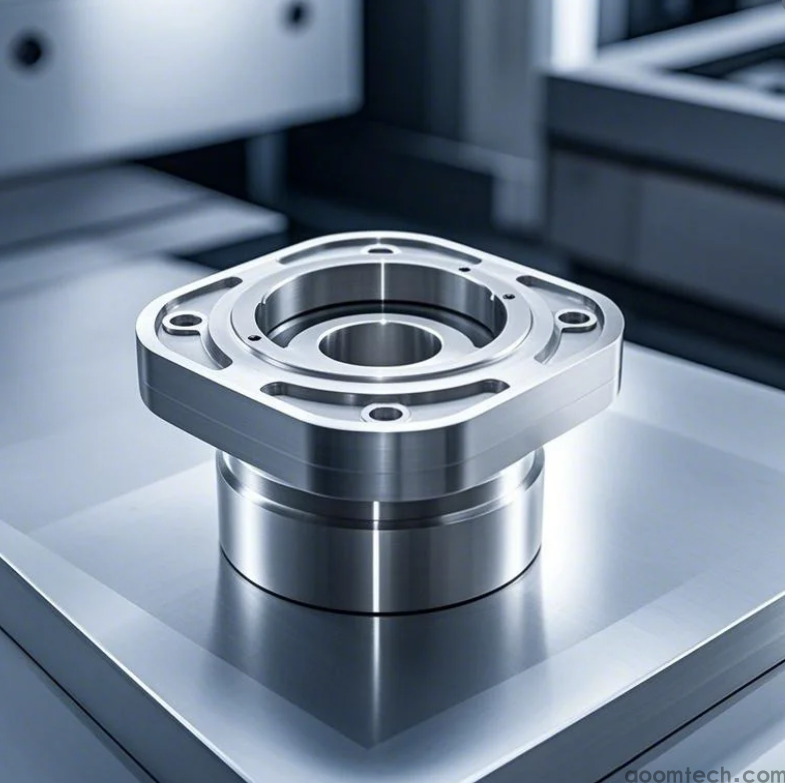

Ask for a Portfolio: Any reputable shop will have a gallery of past projects. Scrutinize the complexity and finishes of those parts. Do they match the level of quality you need?

Request a Physical Sample: If your order is substantial, don't be shy to ask for a sample part. Holding a finished piece in your hand tells you more than a hundred brochures. You can check the surface finish, tolerances, and overall feel. I do this myself for new suppliers – it's a game-changer.

However, it's worth mentioning that the specific process for ensuring consistency across ten thousand identical parts is something I'm not fully clear on. That's a question for their quality engineers.

Communication: The Make-or-Break Factor Everyone Forgets

You could find a shop with the best machines in the world, but if they're terrible at communicating, your project is in for a rough ride.

Responsiveness: Pay attention to how quickly and clearly they respond to your initial inquiries. Are they proactive? If they're slow now, imagine when a problem pops up during production.

Technical Dialogue: Can you have a smooth conversation with their engineer? You want a partner who understands your requirements and can offer suggestions, not just an order-taker. A good shop will ask lots of questions to fully grasp your needs.

Navigating the Tricky Question of Cost

Let's talk money. The lowest quote can be tempting, but it often comes with hidden risks.

Get Multiple Quotes: Don't just go with the first or the cheapest. Get at least three detailed quotes to understand the market rate for your project.

Understand the Pricing Structure: Ask what's included. Does the price cover materials, setup, and finishing (like anodizing or painting), or are those extra? A slightly higher quote that includes everything is often better than a low base price with endless add-ons.

From my experience, a middle-of-the-road price from a communicative and capable shop usually delivers the best overall value, saving you from costly reworks and delays down the line.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C