How Much Does CNC Prototyping Cost? A Clear Pricing Breakdown

Ever had a brilliant product idea, only to be stopped cold by one simple question: "How much will it cost to make a prototype?" 🤔 You're not alone. For engineers, product designers, and startup founders, getting a clear CNC prototyping quote can feel confusing. One supplier gives you a number, another gives you something completely different. It's enough to make you wonder, what exactly am I paying for? Let's break down the mystery behind CNC prototyping pricing, so you can budget smarter and move your project forward with confidence.

So, How IS CNC Prototyping Cost Actually Calculated?

It's not just a random number pulled from thin air! The cost is basically a mix of a few key things. Think of it like a pizza 🍕— you pay for the size, the toppings, and the chef's time. For CNC, you're paying for machine time, material costs, and setup labor. The final price comes from adding up all these parts. While this formula seems straightforward, the real cost can jump around based on your specific project needs.

The Big 3: What Really Drives Your Quote Up or Down

Let's look at the main players that decide your final bill.

1. Machine Time & Complexity: This is a huge one. A simple block with a few holes is quick and cheap. But a part with complex curves, deep pockets, and super tight tolerances? That takes the machine much longer to make. More machine hours directly mean a higher cost. It's like taxi fare, but the meter is running on a super-precise robotic arm.

2. Your Material Choice: The raw block of material you start with has a price tag. Standard aluminum is a common and relatively affordable choice. But if you need something like titanium, stainless steel, or a special engineering plastic, the material cost can be significantly higher. It's the difference between building with pine wood versus a solid piece of oak.

3. Setup & Labor: Before the machine even starts, a technician needs to program it, set up the tools, and secure the material. This is the setup cost. For a one-off prototype, this setup fee is a bigger chunk of the total price. However, if you're making five or ten of the same part, that setup cost gets spread out, making the cost per part much lower. This is why volume matters.

Wait, There's More? Other Factors That Sneak Into the Bill

Beyond the big three, a few other things can affect your final number.

Post-Processing: Do you need a smooth, painted finish? Or maybe a special coating? Processes like sandblasting, anodizing, or painting are extra steps that add both time and cost. A part straight off the machine will have visible tool marks — which is fine for some functional tests, but maybe not for a showroom model.

Tolerances and Quality: This one is subtle but important. Needing a dimension to be accurate within ±.05mm is a whole different ball game compared to ±.5mm. The tighter the tolerance, the more careful and slow the machining needs to be, which increases the price. You have to ask yourself, "Do I really need that insane level of precision for this prototype?" Sometimes, good enough is perfect.

A Little Secret: How to Get a Better Price

Okay, so costs can add up. But here's a pro tip: design for manufacturability. I've seen many designs that are more complex than they need to be. A small change, like increasing the radius of an internal corner, can allow the machine to use a larger, faster-cutting tool, slashing the machining time. Sending a clean, ready-to-machine 3D CAD file also helps the supplier give you a faster and more accurate quote, avoiding back-and-forth emails. It shows you know your stuff.

Getting Your Own Accurate Quote (Without the Guesswork)

By now, you should have a much clearer picture. The cost isn't a mystery; it's a direct result of your design choices. To get the most accurate price, be ready to share your CAD files and tell your supplier your material preference, desired quantity, and any post-processing needs. This gives them everything required to calculate machine time and other factors precisely.

Understanding this process puts you in the driver's seat. You can now have an informed conversation with your manufacturing partner. If you have a design ready and want to see how these factors play out in a real quote, why not get in touch with a specialist? They can review your files and give you a detailed, no-obligation breakdown. 👉 Click to connect with our online service team for a personalized quote assessment!

How is the price calculated fo

How is the price calculated fo

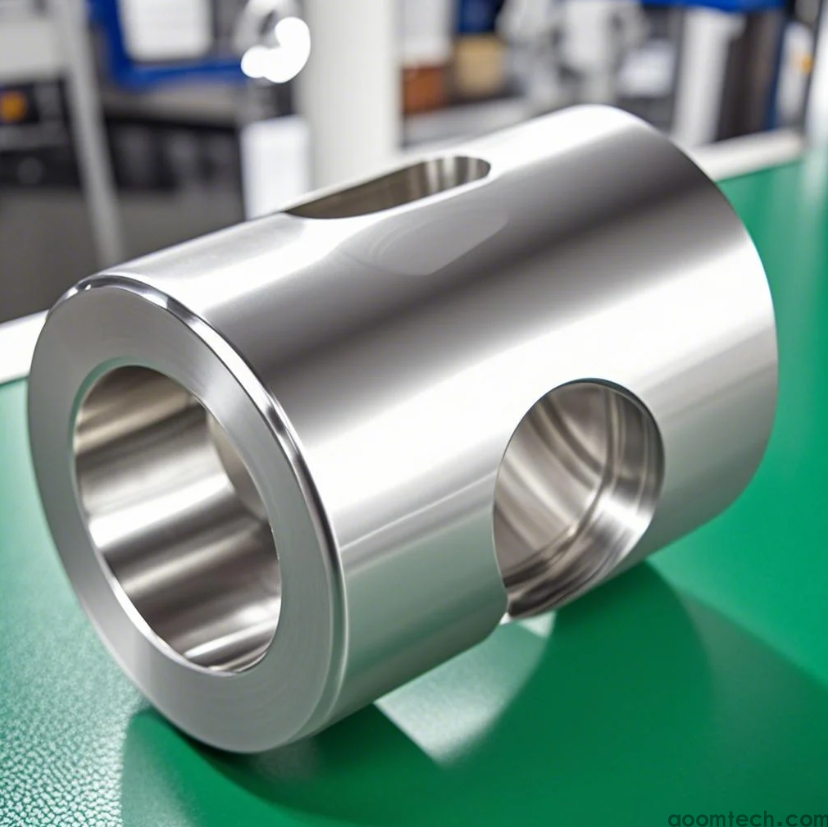

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C