How to Ensure Precision in High-Volume CNC Machining: A Practical Guide

You're managing a big project. Thousands of parts need to be identical, down to the last micron. The pressure is on. 😥 The question keeping you up at night is simple but critical: Can precision really be guaranteed in high-volume CNC machining? We've all heard the promises, but when the order is for 10,000 pieces and not just 10, doubts can creep in. Let's cut through the noise and look at what it genuinely takes to maintain accuracy, batch after batch.

🤔 The Core Question: Is Consistent Precision Even Possible?

First things first, let's tackle the big question head-on. The straight answer is: Yes, but it's not automatic. It's a result of a controlled system, not luck. Think of it like a Michelin-star kitchen. They can produce the same perfect dish hundreds of times a night not because the chef gets lucky every time, but because of meticulous processes, quality ingredients, and constant tasting. High-volume CNC precision works the same way. It's achievable through a combination of the right technology, rigorous processes, and a culture of quality control. However, it's crucial to understand that "perfection" in the physical world always has a tolerance; the real goal is to stay consistently within those predefined limits.

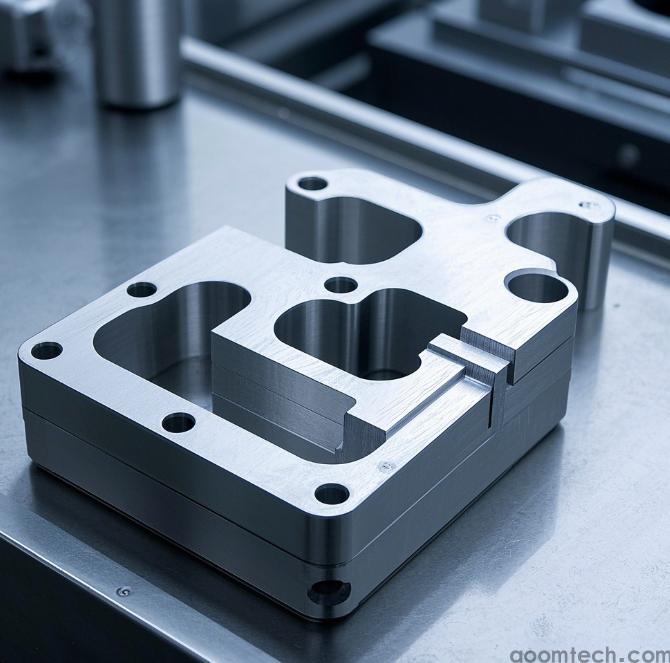

⚙️ The Foundation: Your Machine Tool Matters More Than You Think

You can't expect a budget car to win a Formula 1 race. Similarly, the machine tool is the heart of precision.

- Rigidity and Stability: Heavy-duty machines vibrate less. Less vibration means smoother cuts and better surface finishes, especially when running for long hours.

- Thermal Stability: As machines work, they heat up. This expansion can mess with accuracy. Higher-end machines are built with materials and systems to compensate for thermal growth, a feature that becomes non-negotiable in long production runs.

- Feedback Systems: Precision scales and encoders constantly tell the machine where the tool actually is, allowing it to correct any tiny deviations in real-time. It's like having a GPS that constantly recalibrates.

But here's the thing – I'm not an expert on the specific metallurgy used in every machine frame. The exact mechanism of how different alloys manage heat and stress is a bit outside my wheelhouse, but the outcome in terms of performance is undeniable.

🔧 The Unsung Hero: Tooling and Setup Strategy

Even the best machine is only as good as its tool. For large batches, your approach to tooling needs to be smart.

- Tool Life Management: This is huge. Cutting tools wear down. We use predictive tool-life monitoring to change tools before they start producing bad parts. It's like changing your car's oil based on mileage, not waiting for the engine to smoke.

- Fixture Design: How you hold the part is everything. A poor fixture can flex, allowing the part to move during cutting. For high volumes, custom, rigid fixtures that locate parts identically every time are a must-have investment.

- First-Article Inspection (FAI): Before the "GO" button is pressed for the full batch, the first few parts are meticulously measured. This step is your final check to ensure the entire setup is perfect.

👁️ The Guardian: In-Process Quality Control

You can't just set it and forget it. Continuous monitoring is what separates hope from a guarantee.

- Probing Systems: Many CNC machines can be equipped with probes. Think of them as the machine's "touch" sense. They can automatically check part dimensions during the production cycle and even adjust the machine offsets if it detects a drift. This is a game-changer.

- Statistical Process Control (SPC): This sounds technical, but it's simple in concept. We regularly measure sample parts and plot the data on a chart. This lets us see trends – is a dimension slowly getting larger? – and fix the cause before any parts fall out of tolerance. This data-driven approach perhaps suggests that most precision failures are predictable and preventable, not random.

Having said that, even with all this technology, a skilled operator's intuition is still valuable. They might hear a slight change in the sound of the cut that signals a problem before the data does.

💡 A Final Thought: It's a Partnership

From my experience, ensuring precision at scale isn't just a checklist for the manufacturer; it's a two-way street. Providing a clear, comprehensive print with well-defined tolerances is half the battle. Knowing which dimensions are critical and which have more wiggle room helps us focus our energy where it matters most. This collaboration, from design to delivery, is the ultimate key to turning a question of "can we?" into a resounding "we did." 🚀

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C