How to Choose a CNC Precision Part Service: A Practical Guide for Buyers

Feeling overwhelmed sifting through dozens of CNC machining shops, unsure which one truly delivers on quality and reliability? You're not alone. Finding a partner for your precision parts isn't about luck—it's about knowing what to look for. Let's cut through the noise and figure out how to choose a CNC precision part service that won't let your project down. 🤔

What's the First Thing I Should Check?

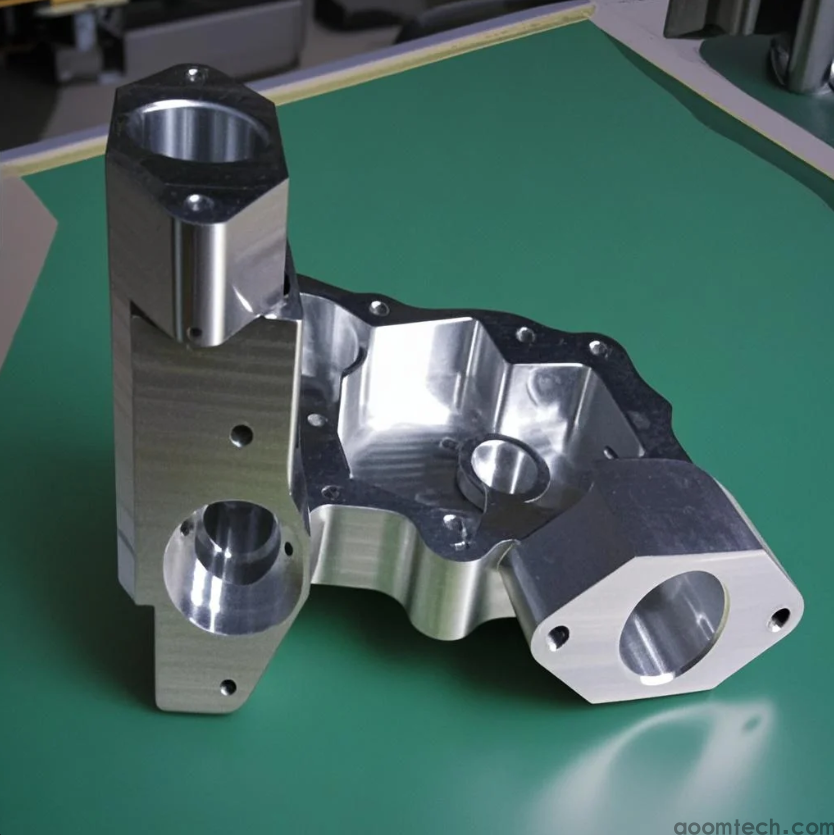

The very first thing isn't the price. It's their equipment and capabilities. A shop might talk a big game, but their machines do the real talking. You want to see if they have the right tools for your job. Think about the materials you use, the tightest tolerances you need, and the size of your parts.

Do they have 5-axis machines for complex geometries? What about their inspection equipment? A capable shop will proudly display this information. I often see buyers get stuck with a supplier because they didn't ask these questions upfront. Don't assume—verify.

Okay, But How Do I Gauge Their Real Quality?

This is where it gets real. Anyone can say they have a "quality system." You need proof. Ask for it. A reputable service provider should be able to provide:

- Documented Quality Certifications: While certifications like ISO 9001 are a good sign of a structured system, they don't automatically guarantee perfect parts every time. They do, however, suggest a commitment to consistent processes.

- First Article Inspection Reports: This is gold. It shows you exactly how their first part measured up against your drawing. It's a snapshot of their attention to detail.

I'd even suggest sending them a test project if the volume justifies it. It's the ultimate trial run. Seeing is believing. 👁️

Is Communication Really That Big of a Deal?

In my experience, yes, it's a huge deal. A technically perfect shop that's slow to respond or doesn't understand your needs can become a nightmare. You need a partner, not just a processor.

Pay attention from the first contact. Are they responsive? Do they ask clarifying questions about your application? A good engineer or sales contact will try to understand the "why" behind the part, not just the "what" on the drawing. This collaborative approach can often lead to design for manufacturability suggestions that save you time and money.

That said, the specific dynamics of what makes a perfect client-supplier communication flow can vary a lot from one project to another. Sometimes a very hands-off approach is what you want, other times you need constant updates. It's worth figuring out what you need early on.

Let's Talk About the Elephant in the Room: Price

We all want a good deal. But with precision machining, the cheapest option is often the most expensive mistake. Price should be a factor, but not the factor.

A suspiciously low quote might indicate that the shop is cutting corners—maybe on material certification, inspection time, or operator skill. Instead of just comparing bottom-line numbers, try to understand what's included in the quote. Does it include full inspection? Material certs? Surface treatment?

A transparent quote builds trust. It shows they have nothing to hide. Value over price, every time. 💰

So, What's the Final Step?

You've checked their capabilities, vetted their quality, tested their communication, and reviewed a quote. There's one more thing: making the decision with confidence.

Choosing a CNC precision part service is an investment in your product's success. It's a partnership. While a meticulous selection process dramatically increases your chances of success, the unique pressures of your specific production timeline could always introduce unforeseen variables.

If you're currently evaluating partners and need a service that prioritizes clear communication, rigorous quality checks, and transparent pricing, why not start a conversation? Reach out to our team today for a no-obligation quote and see the difference a dedicated partner can make. ✨

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C