How to Choose a Reliable CNC Machining Service: A Practical Guide for Buyers

Feeling overwhelmed by all the CNC machining options out there? 🤯 You're not alone. You need parts made, and you need them to be perfect—on time and on budget. But with so many shops promising the world, how can you tell which one will actually deliver? This guide cuts through the noise and gives you the real-world checklist we use to find partners we can trust.

What Exactly Makes a CNC Service "Reliable"?

It's more than just having fancy machines. A reliable service is one that makes your life easier, not harder. Think about it: they communicate clearly, deliver what they promise when they promise it, and the quality is consistently good. It's that feeling of trust where you don't have to worry about the parts once you've placed the order. That's the goal we're aiming for.

Communication is Key: Do They Actually Listen?

This might be the most important point. A great shop doesn't just take your file and run. They ask questions.

Look for these signs:

• They respond to your emails and calls quickly. 🚀

• They ask clarifying questions about your design and its use.

• They explain things in a way you can understand, without too much confusing jargon.

If a shop isn't communicative *before* you give them money, imagine what it will be like afterward. However, it's worth noting that sometimes a very technical engineer might be focused on the details rather than smooth talk, so you have to balance communication style with technical expertise.

Checking Their Work: How to Judge Quality Without Being an Expert

You might not be a machining guru, and that's okay. You can still get a good sense of their commitment to high-quality results.

Here's what you can do:

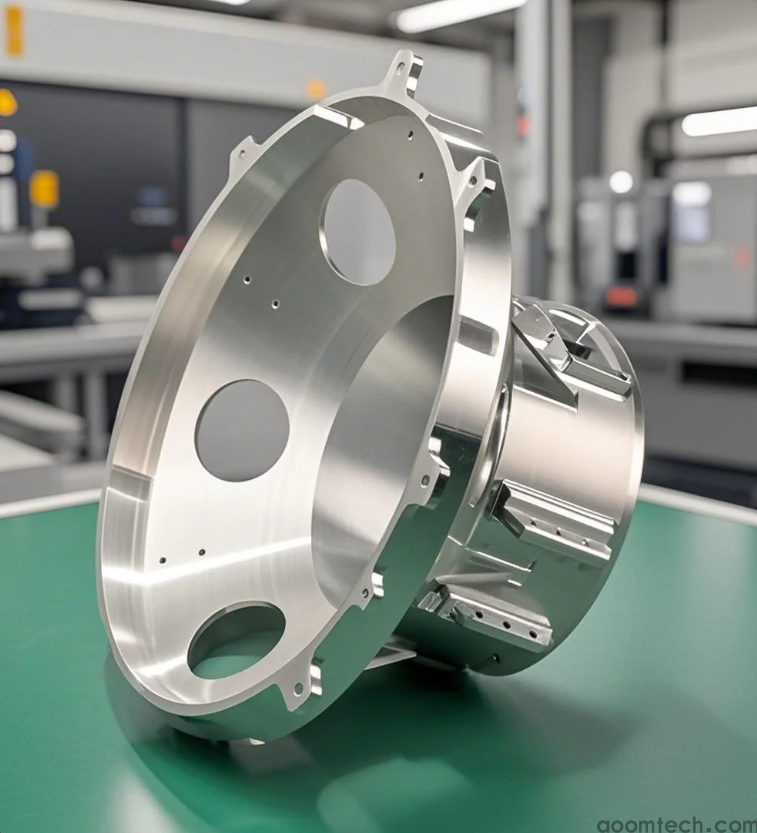

• Ask for photos or examples of past work, especially on parts similar to yours.

• See if they have a quality control process. Do they check parts during production? What tools do they use?

• Read reviews or ask for references. What are other customers saying?

A little bit of digging here can save you from a huge headache later. A few bad parts can stop your whole project.

The Right Fit: Big Shop or Small Specialist?

This is a classic dilemma. A huge company with 100 machines might seem like the safe choice, but is it?

• Large Shops are great for huge volumes, but your smaller order might get less attention.

• Smaller Shops often provide more personalized service. The owner might be the one running your project, which means they really care about your satisfaction.

I often find that for specialized projects or lower volumes, a capable smaller shop can be a much better partner. They're hungrier and often more flexible. But, on the other hand, a big project with tight deadlines might need the muscle of a larger provider. So it really depends on your specific needs.

Getting a Quote: Is the Cheapest Price Really a Good Deal?

Let's be real, price matters. But the lowest quote can sometimes be a trap. 🪤

If one price is way lower than all the others, ask yourself why. Maybe they're using worn-out tools, skipping important quality checks, or they just misunderstood your requirements. These "savings" often lead to parts that don't work, delayed timelines, and ultimately, higher costs.

Perhaps this suggests that the most expensive option isn't always the best either. The sweet spot is usually a fair price from a shop that has clearly understood your project and inspires confidence.

Ready to Find Your Perfect Match?

Choosing a trusted machining partner is a big decision. It's not just about making a single part; it's about building a relationship that helps your business grow. Use this guide as your starting point, trust your instincts, and don't be afraid to ask lots of questions.

If you have a project in mind and want to see what a truly reliable service feels like, why not start a conversation? Our team is here to listen and provide clear, honest answers. Reach out to our online team today for a no-obligation quote and see the difference for yourself. 👨💻

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C