How to Choose a Reliable Fully Automatic CNC Machining Supplier: A Practical Guide

Feeling overwhelmed by the countless options for a fully automatic CNC machining partner? 🤯 You're not alone. Picking the wrong one can lead to delayed projects, wasted money, and a whole lot of headaches. But what if you had a clear, step-by-step checklist to make the right choice? Let's break it down together.

What Exactly Are You Looking For in a Fully Automatic CNC Partner?

First things first, you can't find the right fit if you don't know your own needs. It's like shopping without a list. Before you even start searching, grab a notepad. Ask yourself: What parts do I need? What materials are required? How many pieces? And what's the expected quality level? Getting these details straight helps you talk to potential suppliers like a pro from the very first call.

Key Factors You Simply Can't Ignore

Alright, now that you know what you need, let's look at the supplier. Not all shops are created equal, especially when we're talking about fully automated processes.

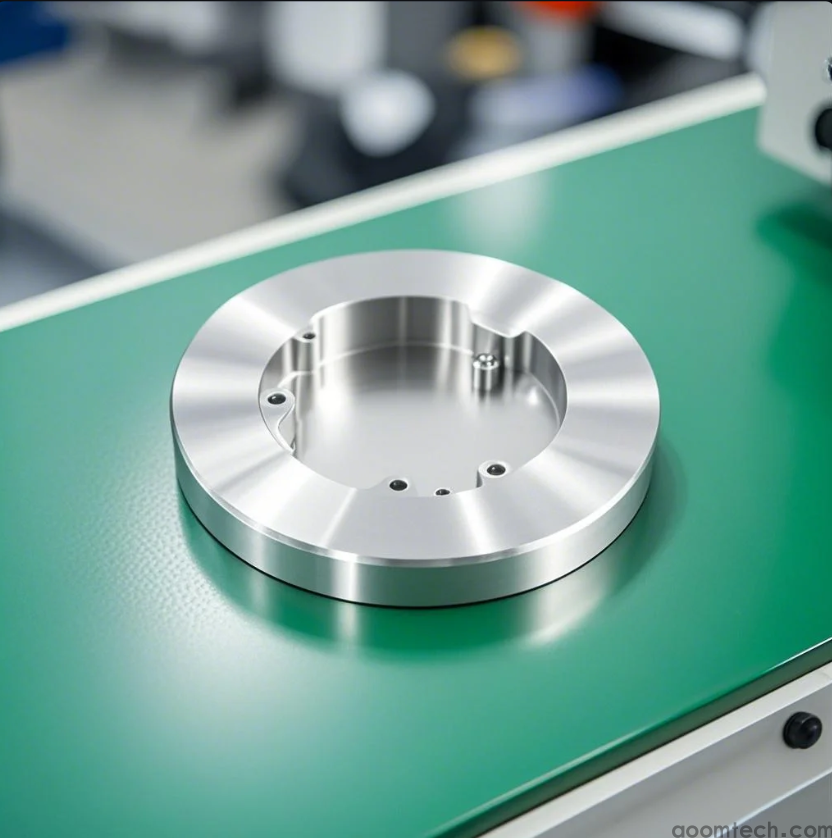

1. Their Tech and Equipment: Do they have modern CNC machines that can run with little human help? Ask them about their equipment. A shop using old machines might struggle with consistency.

2. Experience and Know-How: Have they made parts similar to yours before? Request some case studies or examples. A supplier with relevant experience will spot potential problems before they even happen.

3. Quality Control is King: This is a big one. How do they check their parts? Do they have a proper system in place? Look for things like in-house inspection tools and a clear quality promise. This might suggest they are serious about delivering good parts.

But What About Communication and Service?

Here's a thing we sometimes forget. The best technology in the world means nothing if the communication is poor. You need a partner, not just a order-taker.

Pay close attention to how quickly and clearly they respond to your initial inquiry. Are they asking smart questions? Do they seem genuinely interested in your project? A supplier that's hard to reach during the quoting phase will probably be a nightmare if a problem pops up later. A responsive team can save you from so much stress.

The Price vs. Value Trap: Don't Get Caught!

Of course, everyone cares about cost. But the cheapest option is very often the most expensive in the long run. Super low prices might mean they are cutting corners on material quality, machine maintenance, or skilled workers.

Instead of just comparing the bottom line, think about the total value. What are you getting for your money? Reliable delivery? Great technical support? Consistent quality that means less waste for you? Sometimes, paying a little more upfront is the smartest financial decision you can make. Though, having said that, a surprisingly high price doesn't automatically mean top quality either—you still need to do your homework.

Time to Make Your Move

By now, you should have a much clearer picture. You've defined your needs, you know what to look for in their factory and their people, and you understand the real meaning of value.

The next step is to turn this knowledge into action. Start a conversation with a few potential suppliers using your new checklist. See how they measure up. A truly professional fully automatic CNC machining partner will welcome your questions and be transparent with their answers.

Still have specific questions about your project's requirements? Our technical experts are ready to help you navigate the selection process and ensure you get the precision and reliability your project demands. 👉 Reach out to our online team today for a personalized consultation!

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C