How to Find a Reliable Partner for High-Precision Blister Aluminum Mold CNC Machining

Feeling stuck because your product design is ready, but you can't find a workshop that truly understands high-precision blister aluminum mold machining? You're not alone. Many face this exact hurdle, worrying about quality control and on-time delivery. This guide is here to clear the path and show you exactly what to look for. 🤔

Why is Finding a "High-Precision" Partner So Tricky?

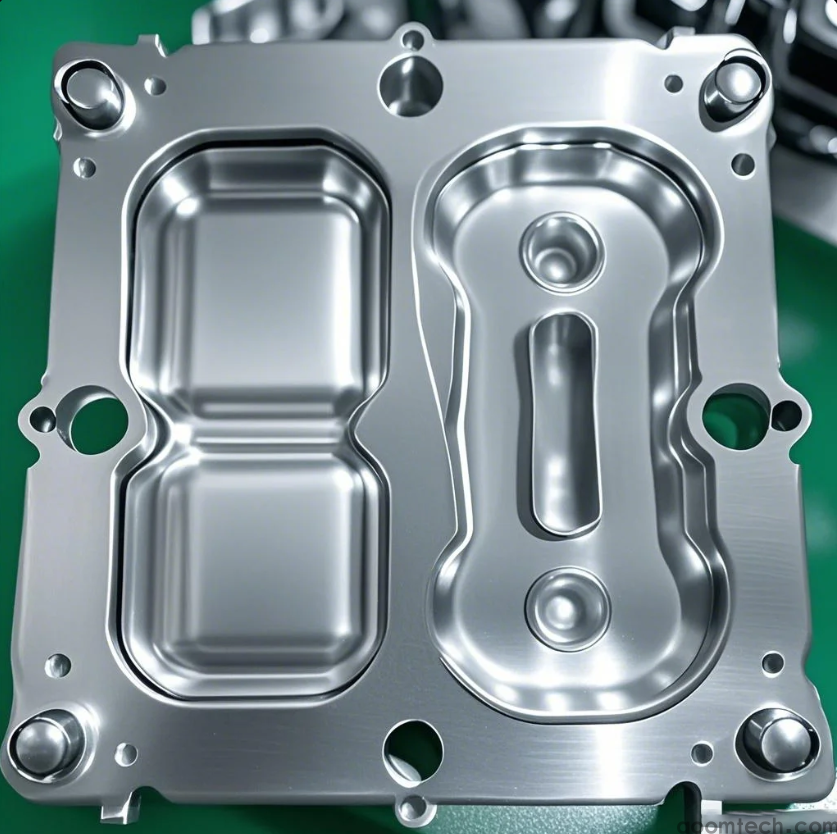

It's not just about finding any workshop with a CNC machine. Blister molds have unique requirements. The surface finish needs to be exceptionally smooth, and the dimensional accuracy must be spot-on to ensure perfect plastic forming every time. A tiny error on the mold can lead to massive production losses. So, the question isn't just "who can do it," but "who can do it right, consistently". While many shops claim precision, their focus might be on larger, more forgiving parts.

What Exactly Should You Look For in a Partner?

Forget just asking for a CNC machining quote. You need to dig deeper. Here are the real things that matter:

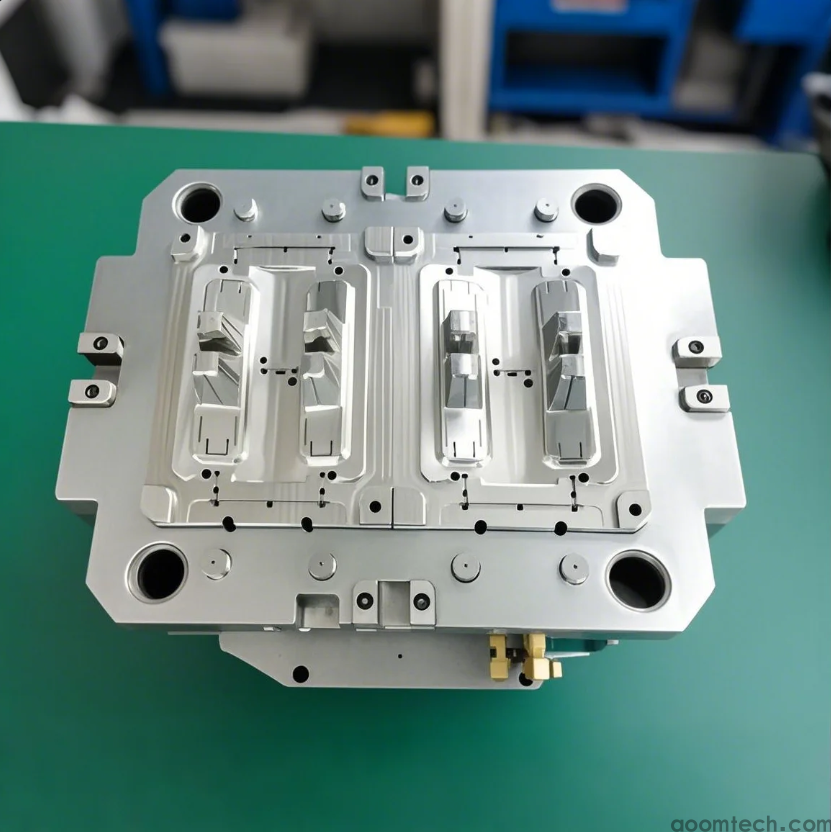

1. Ask to See Their "Book": A reliable partner will have a portfolio of previous work, especially for molds. Don't just look at shiny pictures; ask about the tolerances they held and the materials they've worked with.

2. Talk About Their Machines (But Not Too Much): Modern, well-maintained CNC equipment is a must. But more important is the skill of the programmer and operator. An old machine in the hands of a master can sometimes outperform a new one with an inexperienced user.

3. Gauge Their Communication: Do they respond quickly? Do they ask intelligent questions about your project? A partner that communicates well from the start is more likely to be transparent throughout the process. This is perhaps the biggest indicator of a smooth project.

The Smart Way to Vet Potential Suppliers

Okay, you have a few names. Now what? Jumping straight into a big order is risky. Here's a safer approach:

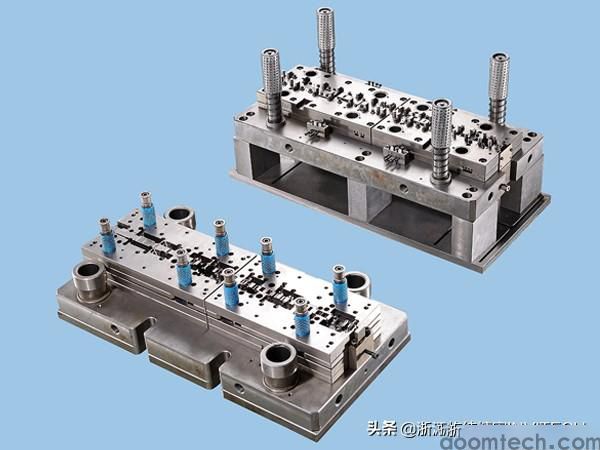

Start with a Small Test Project: A simple test mold or a single cavity. This isn't about getting a cheap part; it's about testing their quality control process, delivery time accuracy, and overall professionalism.

Be Clear About Your Expectations Upfront: Clearly state your required tolerances, surface finish specs, and delivery deadline. See how they react. A good partner will be honest if your demands are challenging and suggest solutions.

I often use this method myself. It might feel like an extra step, but it saves so much headache later. It filters out the talkers from the doers. However, it's worth mentioning that the best shops are often busy, so be prepared for them to be selective as well.

My Personal Take on This Search

From my experience, the hunt for a precision partner is less about the technical specs—which are a given—and more about finding a team that takes ownership of your project. You want someone who sees a potential problem and flags it early, not someone who just follows orders and delivers a sub-par mold. This proactive mindset is what truly separates the best from the rest. It perhaps suggests that the real value lies in the partnership, not just the transaction.

Hopefully, this breakdown helps you navigate your search with more confidence. If you have a specific project in mind and want to connect with a team that gets it, why not reach out for a direct conversation? 👉 [Get a personalized consultation for your mold project]

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C