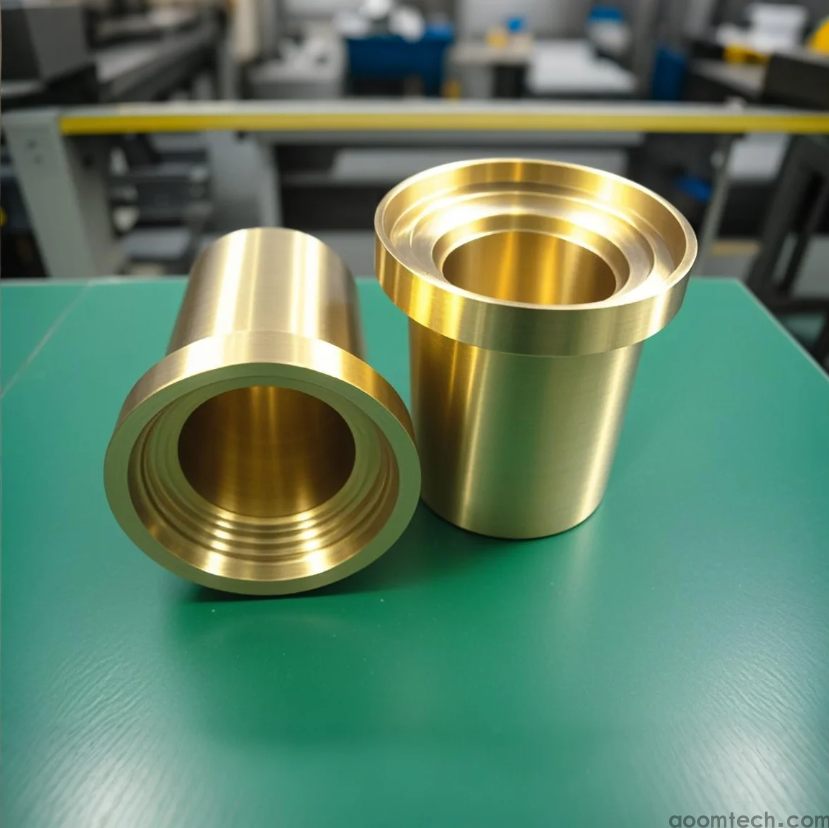

What Tolerance Can You Expect from CNC Machining Custom Copper Parts?

Ever sent a design for a custom copper part, only to have it come back... not quite right? 🤔 Maybe it's a fraction of a millimeter off, but that's enough to throw your whole project out of sync. You're left wondering: "Is this the best they can do?" If you're a procurement manager or engineer sourcing parts, you know that precision isn't just a nice-to-have; it's everything. So, let's cut through the confusion and talk about what level of accuracy, or tolerance, you can realistically expect when you order CNC machined copper parts.

So, What's the Realistic Tolerance for Copper CNC Parts?

The short and direct answer is: for most professional CNC machining services, you can expect a standard tolerance of ±.02 mm to ±.05 mm (±.001" to ±.002"). This is the sweet spot where quality and cost meet for the majority of applications.

But here's the thing—this isn't a fixed rule. It's more of a starting point. The actual precision you can achieve depends on a whole bunch of factors, almost like a recipe where changing one ingredient changes the final dish.

What Factors Can Push Those Tighter Tolerances?

Want to get even closer to perfection? It's possible, but it comes with some "buts". Let's break down what really affects the final numbers on your technical drawing.

• The CNC Machine's Health: A brand-new, high-end 5-axis machine sitting in a temperature-controlled room is in a different league compared to an older, tired one. The machine's condition and calibration are the foundation of precision.

• The Copper Alloy You Pick: Not all copper is created equal. Something like C11000 (Electrolytic Tough Pitch Copper) is pretty good to machine. However, other alloys might be gummier or harder, which can make holding super-tight tolerances a real challenge for the machinist.

• The Part's Geometry and Size: This is a big one. A tiny, intricate feature on a large part is much harder to hold to a tight tolerance than a simple, external dimension. And the larger the overall part, the more things like material expansion can come into play.

• The Machinist's Skill: Let's not forget the human element. An experienced machinist who knows how to fine-tune feeds, speeds, and tool paths can work magic. This is where choosing your partner really matters.

Is Chasing the Tightest Tolerance Always a Smart Move?

It's tempting to just specify the tightest tolerance possible on every dimension, thinking it'll guarantee a perfect part. I see this all the time. However, this approach can actually backfire.

Demanding tolerances like ±.005mm (±.0002") across the board will skyrocket your costs. It requires more expensive machines, significantly more time for setup and inspection, and a much higher risk of parts being rejected for being just a hair out of spec—a hair that might not even matter for your application.

My personal view? Always ask yourself: "Does this dimension really need to be this tight?" Work with your machining partner to identify the critical features that need high precision and allow more relaxed tolerances on non-critical areas. This balanced approach saves money and time without sacrificing the part's function.

How Do You Even Check if They Met the Tolerance?

You can't just trust a caliper for this. Reputable shops use tools like Coordinate Measuring Machines (CMMs) and optical comparators to verify parts. It's a good practice to ask your supplier about their quality control process. How do they check the parts? Do they provide inspection reports with real measurements? This transparency is a hallmark of a quality-focused partner.

Speaking of which, while a CMM gives you hard data, the final test is always how the part fits and functions in your assembly. The numbers on paper have to translate to performance in the real world.

Ready to Get the Precision Your Project Deserves?

Understanding tolerance is the first step to getting the parts you need. The next step is talking to a team that gets it. You need someone who can guide you on what's possible, what's practical, and what's going to deliver the best value for your specific project.

If you're working on a project that needs custom copper parts and you want to have a clear, no-nonsense conversation about precision and price, why not reach out? Our technical experts are ready to review your designs and provide actionable feedback. Get in touch with our online team today to get started.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C