Your Guide to CNC Machining Gears: How to Choose the Right Material

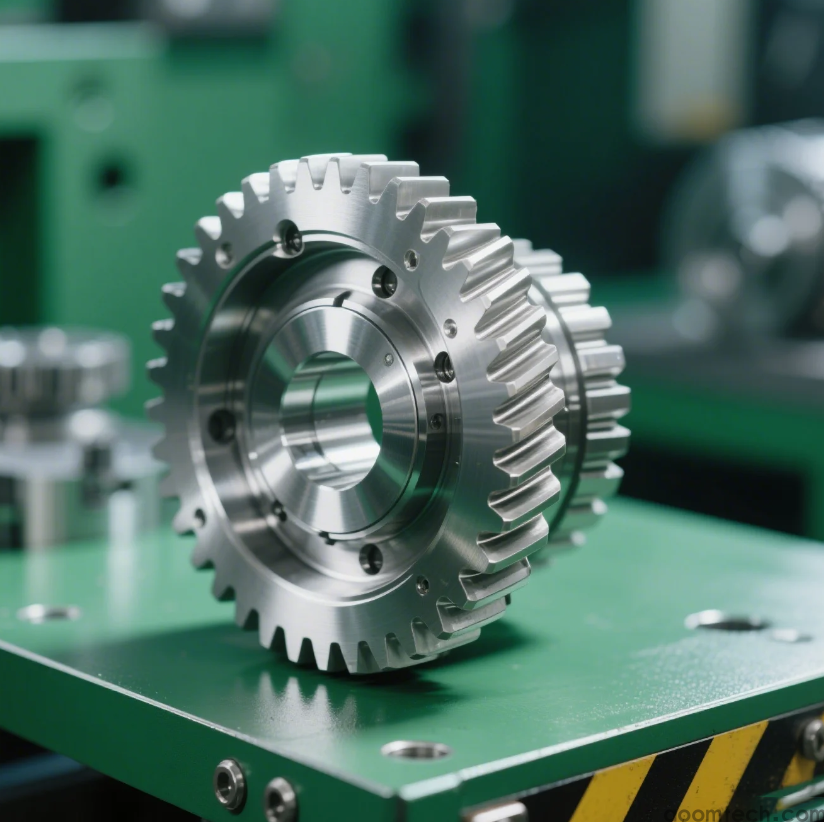

Hey there, fellow engineers and procurement pros! 🛠️ Ever found yourself staring at a design, wondering which material to pick for that critical CNC machined gear? You know the gear's performance, cost, and lifespan all hinge on this one decision. Get it wrong, and it's not just a part that fails—it's downtime, budget overruns, and headaches. So, how do you navigate this material maze without a PhD in metallurgy? Let's break it down together, in plain English.

What's the Big Deal with Gear Material Anyway?

Think of the material as the gear's DNA. It dictates everything: how strong it is, how much wear it can take, if it can handle heat, and of course, the final cost. Picking a material isn't just a checkbox; it's the first and most crucial step in making a gear that actually works. For instance, using a soft aluminum for a high-torque industrial gear is a recipe for disaster, while specifying super-expensive titanium for a low-speed prototype might be overkill. The goal is to match the material to the job, perfectly.

Top Contenders: Common Materials for CNC Machining Gears

So, what are our go-to options? Here are the usual suspects I see in workshops and designs all the time:

1. Steel (Especially 414 Alloy Steel): This is the workhorse. It's tough, strong, and handles wear like a champion. If you need a gear for a high-stress application, steel is often your first port of call. But, it's heavier and can rust if not treated, so keep that in mind.

2. Aluminum (Like 6061): The lightweight hero. 🚀 Perfect when you need to save every gram, like in robotics or aerospace prototypes. It machines beautifully, is corrosion-resistant, and is cheaper. The trade-off? It's not as strong or long-wearing as steel.

3. Brass and Bronze: These are your smooth operators. They have natural lubricity, which means they run quieter with less friction. They're also great at resisting corrosion. I often see them in decorative pieces or low-load, high-motion scenarios. The specific mechanism behind their self-lubricating property is fascinating, though the exact wear dynamics could be a topic for deeper study.

4. Plastics (e.g., Nylon, Delrin/POM): Don't underestimate plastics! They're quiet, lightweight, corrosion-proof, and cost-effective for many non-critical uses. Nylon is tough and has some give, while Delrin is super stable and easy to machine.

How to Actually Choose: It's All About Asking the Right Questions

Okay, you've seen the menu. Now, how do you order? Don't just pick a name. Ask these questions about your gear's future life:

- What Load Will It Carry? High torque and force? Lean towards steel. Light duty? Aluminum or plastic might be fine.

- What's the Operating Environment? Wet or corrosive? Stainless steel or brass/bronze. Need to avoid sparks? Bingo, brass or aluminum.

- Any Noise Concerns? For quiet operation, plastics and bronzes are winners.

- What's the Budget and Timeline? Aluminum and plastics generally machine faster and are less expensive than steel. This is a huge factor in rapid prototyping.

- Do You Need Special Heat Treatment? Things like carburizing can make a steel gear surface incredibly hard. This is where material science gets complex, and perhaps suggests that for ultra-high-performance needs, consulting a specialist is wise.

My Two Cents: The Prototyping Mindset

From my experience, here's a practical tip: consider a two-stage material approach. For your initial prototype and fit-check, use a cheaper, easier-to-machine material like aluminum or Delrin. It lets you test the geometry and assembly fast and cheap. Once the design is locked in, then you can confidently move to the final, more expensive material like hardened steel for production. This saves a ton of money and time compared to machining a flawed design out of costly steel right off the bat.

One Thing That Still Puzzles Me...

I've seen countless material charts, but one area that still feels a bit like a dark art is predicting the long-term micro-wear characteristics between two dissimilar materials, like a specially coated aluminum running against a polymer gear. The theory is one thing, but real-world results can sometimes surprise you. The specific long-term interaction in unique pairings is something I'm still learning about.

Anyway, there you have it. Choosing a material isn't about finding a "best" one, but the right one for your specific situation. Hope this helps you on your next project! 🤝

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C