What Products Can Be Made with 3-Axis CNC Machining? A Practical Guide

Hey there! If you're in manufacturing or product development, you've probably wondered about 3-axis CNC machining. What can it actually make? Is it good enough for your project? Let's cut through the confusion and see what this workhorse technology can really do for you. 🛠️

So, What Exactly Can You Make with 3-Axis CNC?

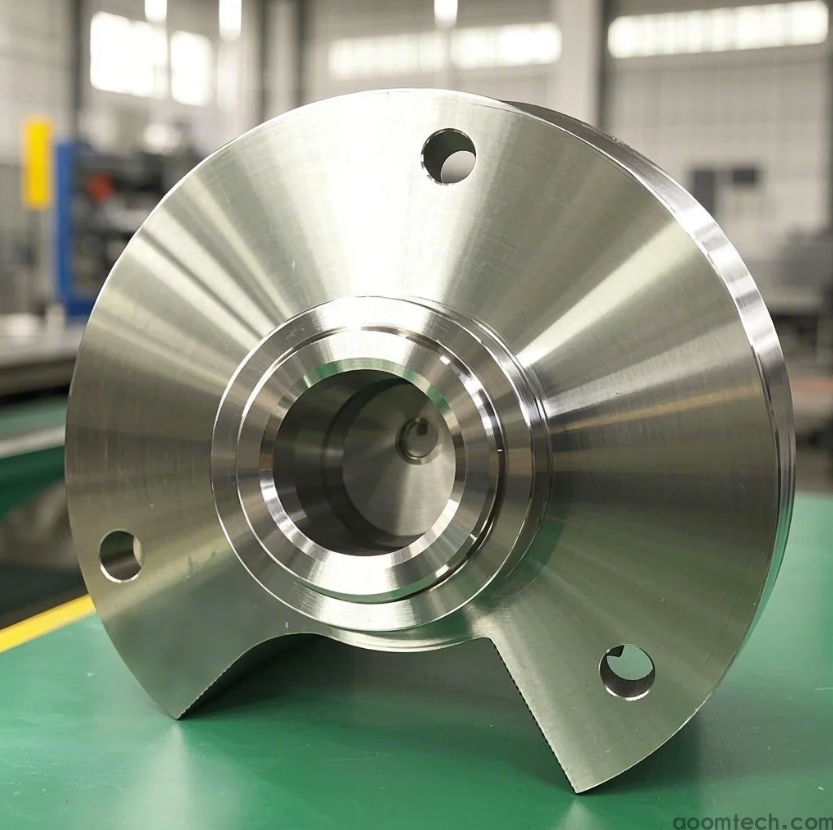

Basically, 3-axis CNC machining can create a huge variety of parts by cutting material from three directions (up-down, left-right, front-back). We're talking about everything from simple brackets to complex enclosures. While it can't handle the craziest undercuts that 5-axis machines can, it's perfect for most common manufacturing needs.

The real beauty is in its versatility – same machine, different tools, countless products.

Everyday Products You Never Knew Were 3-Axis Made

Let's get practical. Here are some common items typically made with 3-axis CNC machines:

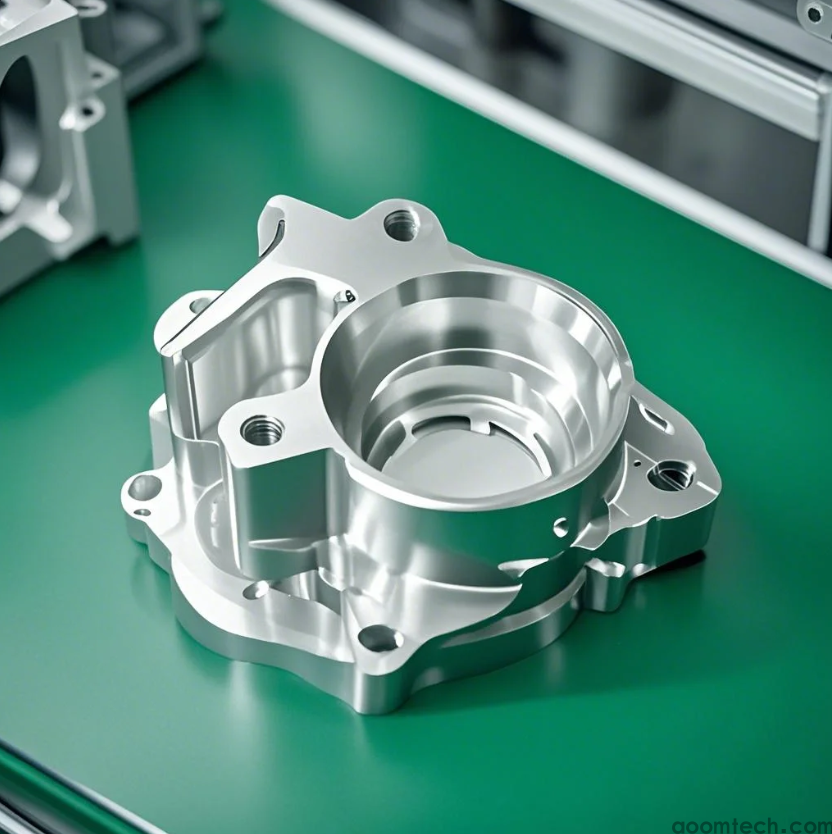

• Electronic enclosures and chassis – those aluminum boxes housing your gadgets

• Mounting brackets and plates – for securing everything from sensors to engines

• Gears and pulleys – the hidden movers in machinery

• Patterns and molds – for casting or plastic injection

• Panel components – with cutouts for switches and displays

Though I should mention – the exact limitations for ultra-complex geometries might need checking with your machinist. 🤔

Where 3-Axis Really Shines (And Where It Doesn't)

Here's my take after years in manufacturing: 3-axis machining hits the sweet spot for probably 70% of components out there. It's reliable, relatively fast, and doesn't cost an arm and a leg.

The big advantage? Simplicity means fewer errors and quicker setup times. But speaking honestly, if your design has deep cavities or requires machining from multiple angles in one setup, you might hit limitations. That being said, many parts can be flipped and repositioned to work around this.

Making the Right Choice for Your Project

When deciding if 3-axis works for you, consider these questions:

• How complex are your part geometries?

• What's your production timeline?

• What's your budget looking like?

For most flat or block-like parts with features on up to three sides, 3-axis is probably your most efficient option. The setup is straightforward, and the process is well-established.

Quick tip: If you're unsure, start with 3-axis – it might handle more than you think while saving costs compared to more complex options.

From my experience, many engineers automatically assume they need advanced machining when good old 3-axis would do the job perfectly. The technology has improved dramatically, offering better precision and surface finishes than ever before.

Need help figuring out if your specific product is a good fit for 3-axis machining? Our technical team can review your designs and suggest the most efficient approach – just reach out through our contact page! 📞

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C