How to Control CNC Machining Accuracy for Large Molds: A Practical Guide

Ever poured a ton of money and time into a massive mold, only to find the final part just... doesn't fit? 🤯 It's a nightmare for any procurement manager or engineer. The problem often boils down to one thing: losing control over CNC machining accuracy. So, how do you actually keep those tiny errors from becoming huge, expensive problems when machining large molds? Let's dive in and get you some answers.

Why is Accuracy Such a Headache with Big Molds?

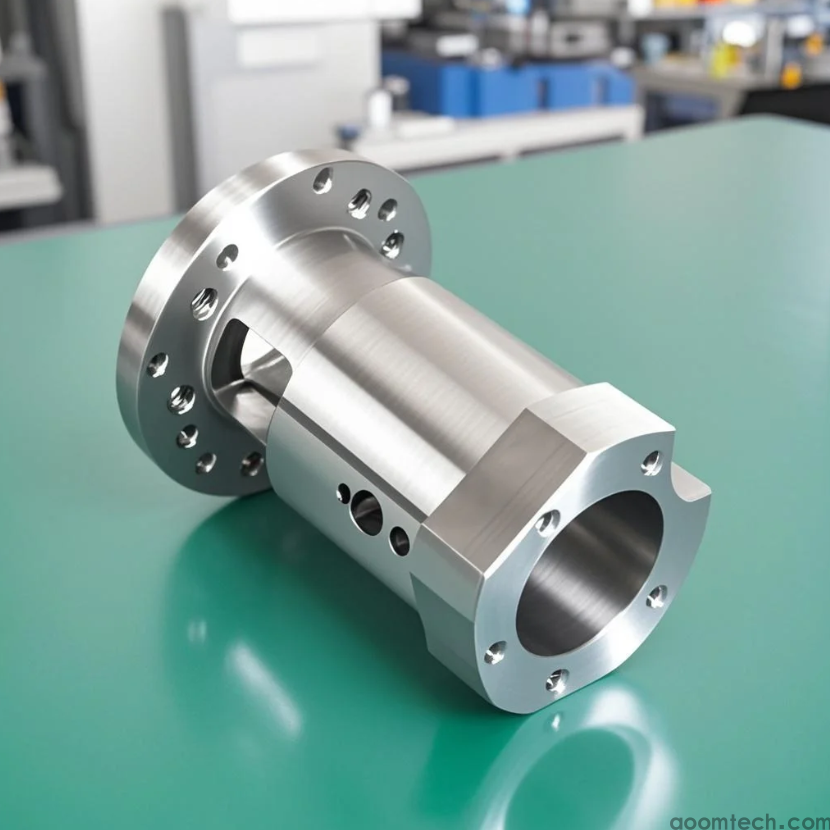

First off, it's not just one thing. Large molds are a different beast. Their sheer size and weight introduce challenges you just don't see with smaller parts. Think about it: the machine itself might sag under the weight, heat from cutting can build up and warp the material, and even the tool can flex more over a long cut. It's a constant battle against physics. While we often blame the machine, the truth is, material stability and toolpath strategy are just as crucial.

So, How Can We Actually Control It?

The key isn't a magic trick; it's a system. Controlling accuracy means managing every step of the process, from the digital model to the final cut. It's about being proactive, not reactive.

Here are the core areas you need to focus on:

1. Machine and Tooling Setup: This is your foundation.

- Use a Robust Machine: You need a CNC machine with a massive work envelope and, more importantly, incredible rigidity to handle the vibrations.

- Tooling Matters: Don't skimp here. Use short, stout tools to minimize flex. I often use tools with a larger shank diameter for heavy-duty roughing—it makes a noticeable difference in stability.

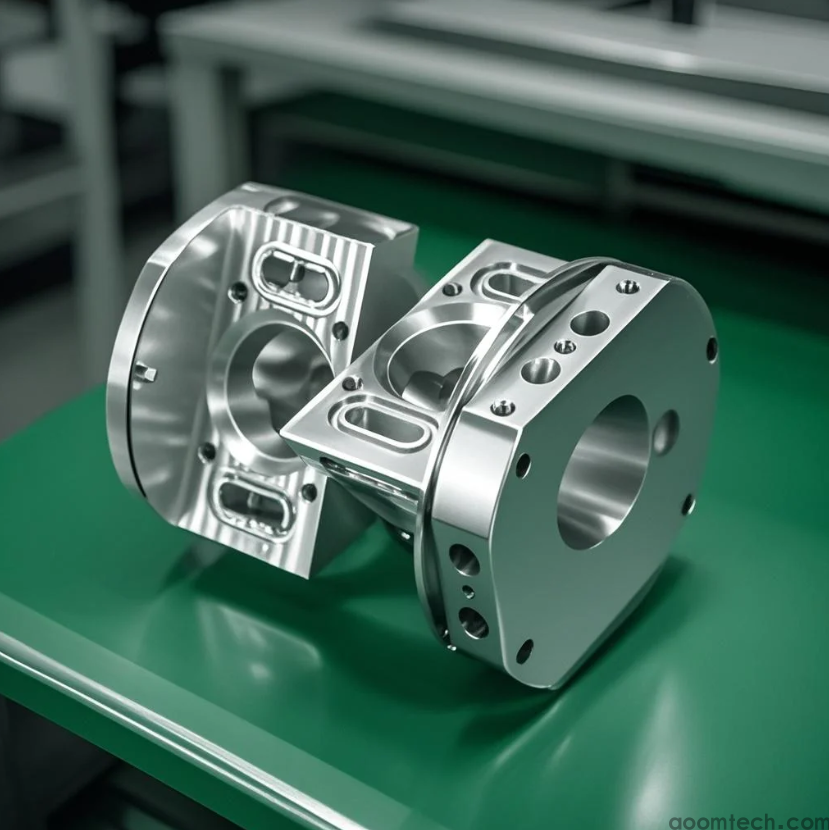

2. Smart Programming and Toolpaths: This is where the real magic happens.

- Climb Milling vs. Conventional Milling: Generally, climb milling provides a cleaner cut and better tool life. But with large molds, tool engagement is critical. Sometimes, a hybrid approach is better to manage stress.

- Take Smaller Bites: Instead of one deep, aggressive cut, use smaller step-downs and step-overs. It's slower, sure, but it puts less stress on the tool and the material, leading to a more stable process and better surface finish. Perhaps this suggests that a gentler approach ultimately wins the race for precision.

3. Taming the Heat and Stress: The invisible enemies.

- Heat is the Enemy: The exact way heat distorts different alloys under long machining cycles can be complex. Using coolant effectively is non-negotiable. But sometimes, with certain materials, a "dry machining" strategy with air blast is better—the specific mechanism depends on the material and is an area worth discussing with your machining partner.

Stress Relief Cycles: After roughing out most of the material, it's a great practice to run a stress relief cycle. This means letting the material "rest" and normalize before you start your finishing passes. It helps the material settle and release any internal stresses you've stirred up.

What About Material Choice and Its Impact?

This is a huge piece of the puzzle. The metal you choose behaves differently. P20 steel is a common choice for its good machinability, but H13 tool steel, while tougher, can be more prone to distortion if not handled correctly. You have to match the material to the mold's lifetime and production volume. However, it must be said that even the best material can be ruined by a poor machining process. The interaction between the material properties and the cutting parameters is what truly defines the outcome.

My Go-To Strategy for Consistent Results

From my experience, consistency beats heroics every time. Here's a simple routine I rely on:

- Verify Your Setup: Double-check workpiece clamping. Any movement is a disaster.

- Tool Presetting: Use a tool presetter to ensure every tool length and diameter is spot-on before it even goes in the machine.

- In-Process Checks: Don't wait until the end. Use probes to check critical dimensions at intermediate stages. It's easier to correct a .1mm error early than to scrap the whole part later.

Controlling CNC machining accuracy for large molds is a meticulous dance. It demands attention to the machine, the tool, the code, and the material all at once. There's no single secret, just a commitment to a disciplined process.

Struggling with a specific accuracy issue on your project? Sometimes a fresh pair of eyes can spot the solution. Why not connect with our technical team for a quick consultation? We're here to help you nail the precision you need. 👍

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C