How to Choose a Small CNC Machining Shop: A Practical Guide for Buyers

Feeling overwhelmed trying to find the right small CNC shop for your project? 🤔 You're not alone. Picking a partner from a sea of options can be tricky, especially when your project's success depends on it. This guide cuts through the noise, giving you a straightforward, step-by-step approach to make a confident decision.

1. Why Look for a Small CNC Shop in the First Place?

Many people automatically think bigger is better, but that's not always the case. Small CNC shops often offer something huge corporations can't: direct communication and flexibility. You're not just a PO number; you can often talk directly to the machinist or the owner. This can mean faster turnarounds on quotes and a partner who's willing to accommodate last-minute changes. However, it's wise to remember that their capacity might be more limited compared to a large factory.

2. The Non-Negotiable: Checking Their Equipment and Tech

Don't be shy to ask, "What machines do you run?" A shop's equipment tells you a lot about its capabilities.

Look for:

• The types of CNC machines (3-axis, 4-axis, or 5-axis).

• The age and condition of their equipment.

• What software they use for programming and design.

While a shop with brand-new 5-axis machines is impressive, it doesn't automatically mean they are the best fit for a simple 3-axis job. The specific mechanism of how machine age impacts final part quality can be complex, but a well-maintained machine, regardless of age, is the real key. A shop investing in its tools is often investing in its customers' results.

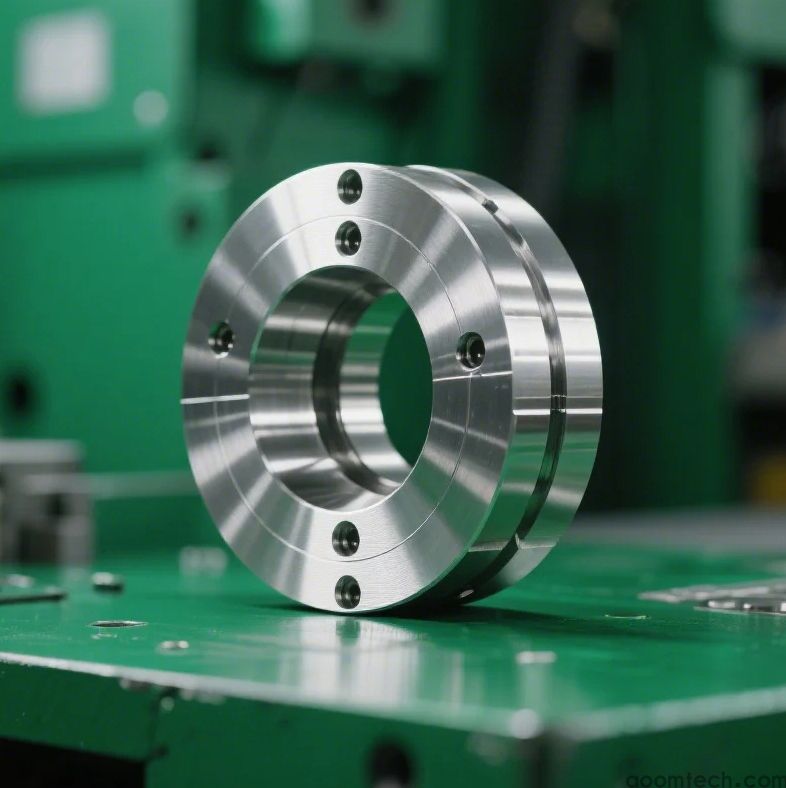

3. The Proof is in the Parts: Evaluating Their Work Quality

A great sales pitch means nothing without the results to back it up. The most critical step is to ask for examples of their previous work.

What to ask for:

• Photos or a portfolio of finished parts.

• Can they provide physical samples?

• Do they work with similar materials to what you need?

Looking at their past work gives you a tangible sense of their skill level and attention to detail. It perhaps suggests their experience with projects of a similar scope to yours.

4. It's Not Just About the Price: Understanding Their Communication

Here's a common headache: you send an RFQ and get a price back with no context. A good shop, especially a smaller one, will be a partner in communication.

Spot the green flags:

• They ask clarifying questions about your design.

• They respond to emails and calls promptly.

• They explain the quote and lead time clearly.

If they aren't communicative during the sales process, it likely won't get better after you pay. I frequently use the initial quote request as a test of their customer service. That said, it's important to be realistic; a one-person shop might not answer a 2 AM email, but they should be professional during business hours.

5. The Final Piece: Making Your Decision

So you've got a few promising shops. How do you choose?

My personal method: I create a simple scorecard. I rate each shop on communication, perceived quality from their portfolio, and value (not just the lowest price). The cheapest option often ends up costing more in delays and headaches. Sometimes the shop that was easiest to talk to and asked the smartest questions is the one that delivers the smoothest project, even if their bid wasn't the absolute lowest.

One area I'm less familiar with is the long-term impact of different shop floor quality control systems on part consistency over a 10-year period. That's a topic for the true experts.

Ultimately, choosing a CNC shop is about finding a balance. You want technical skill, sure, but you also need a responsive partner you can trust. Hopefully, this guide points you in the right direction! 🚀

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C