How to Get an Accurate CNC Machining Quote: A Step-by-Step Guide for Buyers

Feeling frustrated because every CNC machining quote you get seems to be all over the place? 🤔 You send out your design, and the numbers that come back are a mystery—some too high, some suspiciously low. How can you be sure you're getting a fair price without sacrificing quality? This guide is here to pull back the curtain. We'll walk you through the simple steps to secure a transparent and accurate quote, every single time.

What Do Manufacturers REALLY Need to Give You a Good Price?

Think of it like this: asking for a quote with just a sketch is like asking a chef to cook a meal without knowing the ingredients. 🧑🍳 They might guess, but the result won't be what you wanted. To get a spot-on quote, you need to provide a clear package. Here’s the checklist I always use:

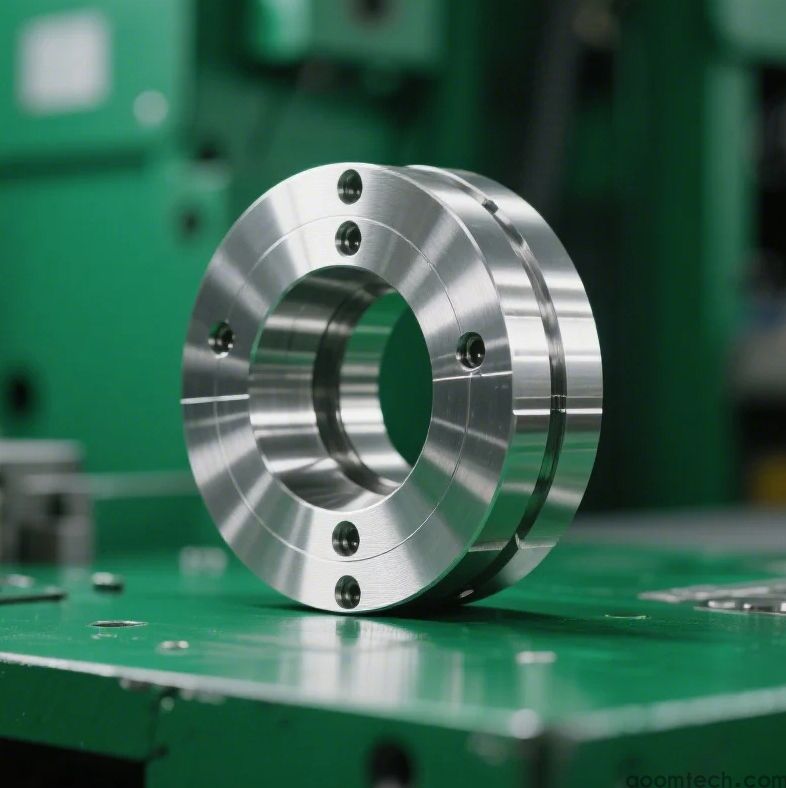

1. A Detailed Drawing or 3D Model: This is non-negotiable. It's the blueprint for your part. Make sure it includes all the dimensions, tolerances (how precise the measurements need to be), and any special notes.

2. Your Target Material: Are you thinking aluminum, stainless steel, or maybe a special plastic? The material cost is a huge part of the final price.

3. Quantity Needed: This one is a game-changer. Making one piece is very different from making ten thousand. The cost per part usually drops with higher volumes.

4. Surface Finish Requirements: Does it need to be super smooth, painted, or anodized? These extra steps add time and cost.

Why Do Quotes from Different Shops Vary So Much? 🤷♂️

It's confusing, right? You send the same file to three shops and get three wildly different numbers. This doesn't always mean someone is wrong. Sometimes, it's about what's not being said.

One shop might be including the cost of special inspection tools, while another isn't. One might be using a more expensive but faster machine, which could be worth it if you're in a hurry. The cheapest quote might be using a lower-grade material, or perhaps they missed a complex feature in your design that will cause problems later. This is why understanding the breakdown of the quote is more important than just the bottom-line number.

The Secret Sauce: Asking These 3 Questions

Okay, so you've got a few quotes in hand. Now what? Don't just pick the lowest one. To truly gauge accuracy, you need to dig a little deeper. Here are the three questions I always ask a supplier:

1. "Can you provide a basic cost breakdown?" This helps you see what you're paying for—material, machine time, and setup. It shows you where your money is going.

2. "What is your experience with similar parts?" A shop that has made parts like yours before will be more efficient and might spot potential issues you missed. This experience adds value.

3. "Are there any design changes that could lower the cost without hurting the part's function?" This is a pro-move. 🧠 Sometimes a tiny tweak to the design can make it much easier and cheaper to produce. A good partner will tell you this.

My Personal Take: It's More Than Just Price

Look, I get it. Budget is king. But after years in this field, I've learned that the cheapest option can often become the most expensive one. A part that fails inspection, arrives late, or doesn't fit can bring your whole production line to a halt. 🚧

That said, a shop that communicates clearly, asks smart questions about your design, and provides a detailed quote is usually a shop that does quality work. This relationship is worth its weight in gold. Their higher initial quote might actually save you money and headaches down the road. It's a balance, for sure.

Ready to Get a Quote That Makes Sense?

You're now armed with the knowledge to navigate the world of CNC machining quotes confidently. No more guesswork. You know what information to provide, why quotes differ, and what questions to ask. This puts you in control.

If you have a project in mind and want to test these principles with a partner who values clarity, why not start a conversation? Reach out to our team today for a transparent and detailed quote on your CNC machining needs. We're here to help you get it right from the start. 😊

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C