Precision CNC Aluminum Parts Customization: A Guide to Quality and Application

Hey there, are you a project manager or engineer feeling stuck because you need a specific aluminum part, but off-the-shelf options just don't cut it? 😩 You're not alone. Many of us face this exact problem when standard components fail to meet our unique design or performance needs. This is where precision CNC aluminum parts customization comes into play. But what does it really take to get high-quality, custom-machined parts that fit your project perfectly? Let's dive in and break it down together! 👇

What Exactly is Precision CNC Customization for Aluminum Parts?

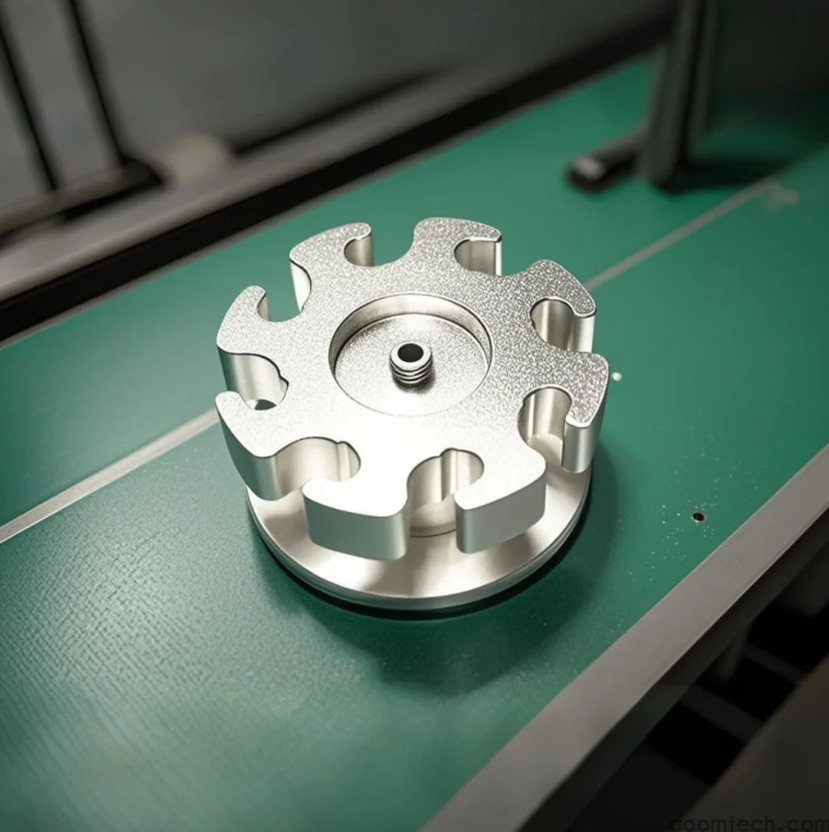

At its core, it's all about using computer-controlled machines to shape a block of aluminum into a highly accurate, custom-designed component. Think of it like a super-precise sculptor that follows your digital blueprint to the letter. The key here is precision – we're talking about tolerances that can be as tight as a few human hairs! This process is perfect for creating parts that need to fit, function, or perform in very specific ways that standard parts can't. While the basic idea is using a machine to carve metal, the real magic happens in the planning and execution, which perhaps suggests that the choice of partner matters just as much as the technology itself.

Why Choose CNC Machining for Your Custom Aluminum Parts?

You might be wondering, why go through the trouble of custom machining? Well, let's look at some big reasons:

✔️ Super Flexibility in Design: Almost any shape you can design on a computer can be made. Need a weirdly shaped bracket or a housing with complex internal channels? No problem.

✔️ Incredible Strength and Light Weight: Aluminum itself is a champ here – it's strong but doesn't weigh your product down. This balance of strength and weight is a huge win for many applications.

✔️ Great Looks and Surface Finish: Beyond just working well, CNC machined parts can look fantastic. They can be finished to be shiny, matte, textured, or even colored.

✔️ Consistency is Key: Once the program is set, the machine can produce the same perfect part over and over again. This is crucial for manufacturing.

But, it's worth mentioning that the specific science behind why aluminum responds so well to machining compared to some other metals is a bit beyond my usual deep dive – the exact metallurgical mechanisms are something the material scientists could elaborate on further.

Key Steps in the Custom CNC Aluminum Process

How does it all work? Here's a simplified breakdown of the journey from idea to finished part:

1. You Share Your Vision: This usually starts with a 3D model or a detailed drawing. The more detail, the better!

2. DFM Review (Design for Manufacturability): This is a super important step. A good manufacturer will look at your design and suggest small tweaks to make it easier, faster, or cheaper to produce without messing up your intent. I can't stress this enough – a collaborative DFM phase saves so many headaches later!

3. Programming the Machine: Your design gets translated into a language the CNC machine understands.

4. The Machining Begins: The machine precisely cuts, drills, and shapes the aluminum block.

5. Finishing Touches: The part might be deburred (smoothing sharp edges), polished, anodized, or painted based on your needs.

Where Are These Precision Custom Aluminum Parts Used?

Oh, the places they go! The applications are everywhere once you start looking. From the drone that's capturing amazing aerial footage to the internal components of the medical device that's helping someone lead a better life. They're crucial in automotive prototypes, high-end electronics enclosures, and even in some specialized robotics. The demand for lightweight and durable custom components is truly growing across the board. However, it's important to remember that while the potential is massive, the success of each part still hinges on a clear understanding of its end-use environment.

How to Talk to a Manufacturer for the Best Results?

This is where many projects succeed or stumble. Based on my experience, communication is everything. Don't just send a file and hope for the best. Be ready to discuss:

👉 The Part's Job: What does it do? What forces does it need to handle?

👉 Critical Dimensions: Which features absolutely must be perfect, and which have a little wiggle room?

👉 Your Budget and Timeline: Being upfront about this helps them guide you to the most efficient solution.

A proactive conversation here, in my view, sets the stage for a smooth partnership and a top-quality outcome. It transforms the process from a simple transaction into a collaborative effort to solve a problem.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C