How to Choose Reliable CNC Flange Processing Manufacturers: A Practical Guide

Ever found yourself staring at multiple supplier quotes for CNC flange processing, wondering why prices vary so wildly? 🤔 You're not alone. Many purchasing managers and engineers struggle to identify which manufacturers truly deliver quality without breaking the bank. Let's break down what really matters when selecting CNC flange processing partners.

What Exactly is CNC Flange Processing Anyway?

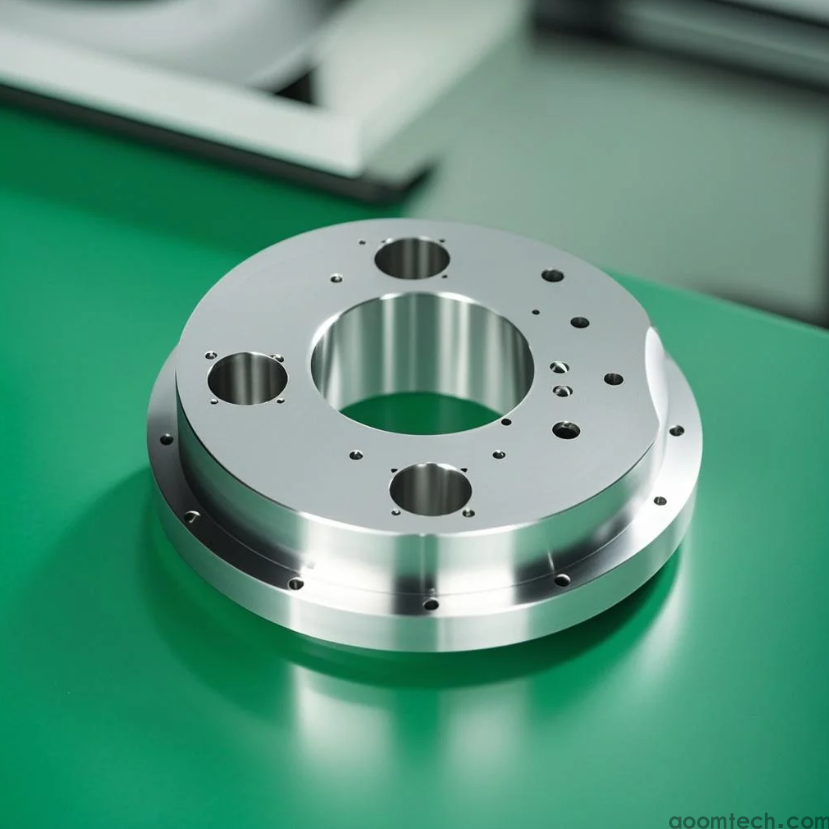

Think of flanges as the connectors that join pipes, valves, and other equipment together. CNC flange processing involves using computer-controlled machines to create these components with precision. The catch? Not all "precision" is created equal. Some manufacturers cut corners on material inspection, while others might use older machinery that affects tolerances.

The real challenge isn't finding manufacturers - it's identifying those who maintain consistency across batch productions. I've seen shops that perform beautifully on samples but struggle with larger orders. That's why understanding their quality control process matters more than their sales pitch.

Key Factors That Separate Good Manufacturers From Great Ones

Let's talk about what actually affects your bottom line:

• Material traceability - Can they provide documentation about raw material origins?

• Equipment maintenance schedules• In-process inspection frequency - How many quality checks happen during production?

Here's something most suppliers won't tell you: the relationship between pricing and inspection frequency isn't linear. Some manufacturers charge premium prices but only do basic dimensional checks. Others include comprehensive testing in standard pricing. Always ask about their quality assurance workflow specifically.

Common Pitfalls in Manufacturer Selection

We've all been tempted by low prices, but let me share what usually happens with the cheapest options. One client saved 30% on paper but ended up with flange surfaces that required additional machining - costing them more in the end. The manufacturer had used improper cutting parameters that created microscopic imperfections.

Another often-overlooked aspect? Communication responsiveness during problem resolution. How quickly do they address issues when (not if) they occur? This might be more valuable than perfect initial samples.

Technical Capabilities Worth Verifying

While most manufacturers list their equipment, few can clearly explain how their machining strategies differ. For instance, their approach to tool path optimization directly affects surface finish quality. Though I should mention, the specific algorithms different CAM software use for generating these paths isn't my specialty area.

What's more telling is asking about their experience with similar projects. A manufacturer specializing in small precision components might not be ideal for large-diameter flanges, even if their brochure says they can handle it. This is where asking for project case studies pays off.

Making the Final Decision

After visiting numerous facilities, I've developed a simple checklist:

1. Request material certificates for their stock

2. Ask for witness samples from regular production runs (not specially made samples)

3. Verify their measurement equipment calibration records

4. Discuss their approach to handling dimensional deviations

One manufacturer once told me "we guarantee ±.01mm accuracy on all dimensions." The reality is that achieving such tolerances consistently across different materials and geometries involves multiple variables. Their confidence perhaps indicated experience, but I'd want to see actual statistical process control data before believing absolute claims.

Remember that the goal isn't finding the perfect manufacturer - it's finding the right partner who's transparent about their capabilities and limitations. The best relationships I've seen involve manufacturers who proactively suggest improvements to designs for better manufacturability.

What has your experience been with CNC flange suppliers? I'm always curious how different industries prioritize these factors - sometimes delivery speed outweighs perfect precision, other times it's the reverse.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C