A Practical Guide to Small-Batch CNC Gear Customization: Cost, Quality, and Lead Time

Hey there, are you an engineer or a procurement manager stuck between needing a few high-quality custom gears and the nightmare of high costs and long waits? 😩 You're not alone. We often think custom machining is only for massive orders, but what if you just need 10, 50, or 100 pieces for a prototype or a specialized machine? This is where small-batch CNC gear customization comes into play, and it's a game-changer. Let's break down how it actually works for smaller projects.

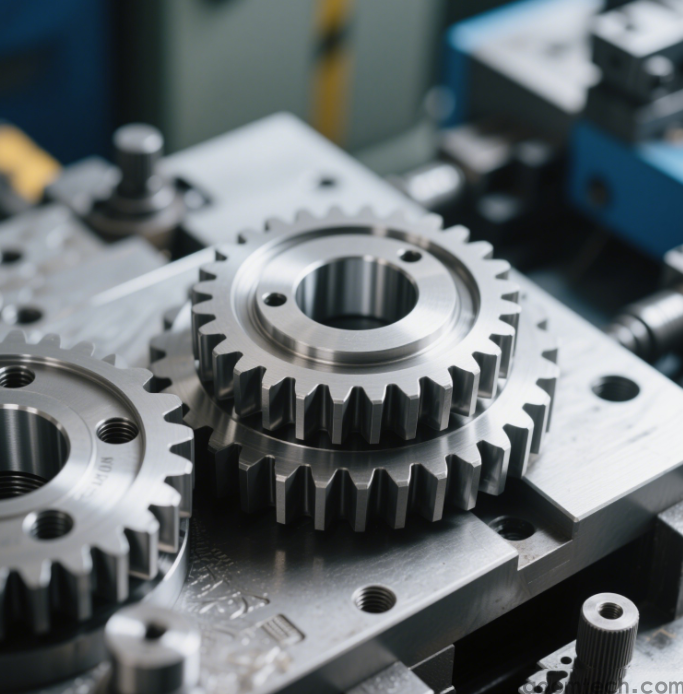

What Exactly is Small-Batch CNC Gear Customization?

At its heart, it's about using computer-controlled machines to produce a limited number of gears tailored to your exact needs. Think of it like ordering a bespoke suit instead of buying off the rack. You get to decide everything – the material, the tooth profile, the tolerances – but without the commitment of a huge production run. This approach is perfect for prototyping, research and development, or repairing legacy equipment where you can't find a replacement part.

Why Choose CNC Machining for Small Batches? The Real Deal

You might wonder, "Is CNC even cost-effective for small numbers?" It's a fair question. While the setup has a cost, the payoff is huge for low-volume needs.

✅ Unbeatable Flexibility: Need to change a design? It's often just a matter of tweaking the digital file. This is something traditional methods struggle with.

✅ Top-Notch Consistency: Every single gear in your batch will be virtually identical. This precision is crucial for smooth operation and reducing noise in your machinery.

✅ Speed for Development: For getting a product from concept to testing quickly, CNC is often the fastest route. The lead time from approved design to finished parts can be surprisingly short.

However, it's not a magic bullet. The initial programming and setup time does mean the cost per part is higher than in mass production. But for the value you get in precision and flexibility, it's often the smartest choice.

How Much Does a Small Batch Actually Cost? Let's Be Honest.

This is the million-dollar question, right? There's no single price tag, but the cost hinges on a few key things. I see a lot of people get frustrated because they expect a simple answer, but it's a bit more nuanced.

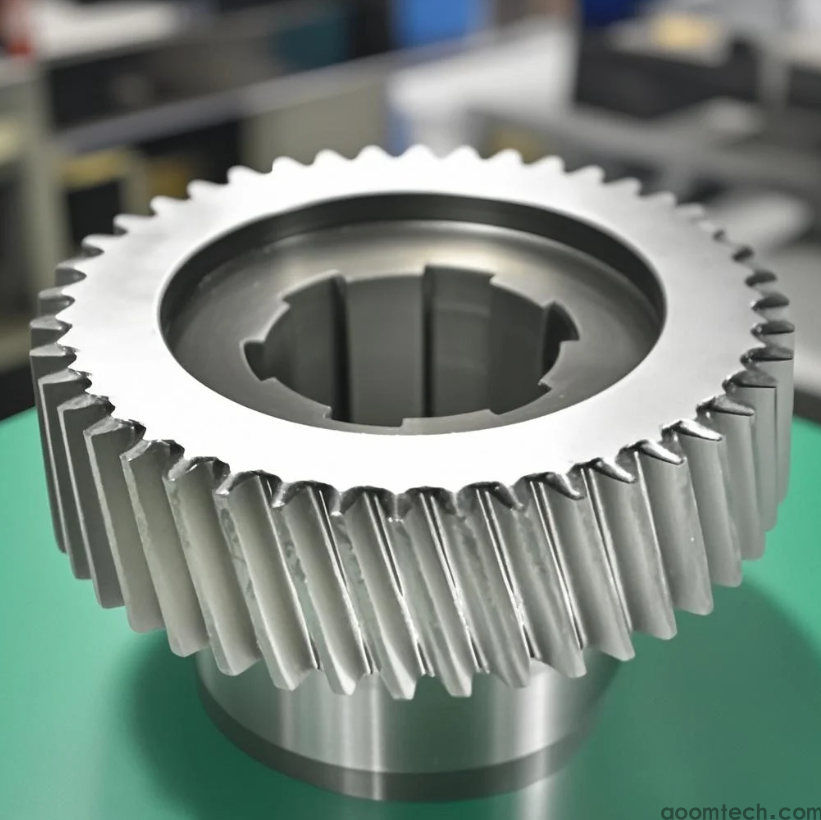

📌 The Gear Design Complexity: A simple spur gear is far cheaper than a complex spiral bevel gear. More complex shapes mean longer machining time and more sophisticated programming.

📌 The Material You Pick: Common materials like aluminum are more budget-friendly. Switching to stainless steel or specialty alloys will increase the cost.

📌 The Quantity and Tolerances: Obviously, 50 gears cost more than 10, but the cost per piece usually drops. Also, demanding extremely tight tolerances can significantly drive up the price and time.

From my experience, the best way is to get a direct quote from a supplier with your CAD drawings. This might suggest that the pricing models themselves can be a bit opaque, and it's an area where the industry could be more transparent.

What's the Typical Lead Time? From File to Finished Gear.

Time is money, and we all want our parts yesterday. For a typical small batch, you're generally looking at a timeline that includes design review, machine programming, actual production, and any post-processing.

While many shops can turn around simpler jobs in a matter of days, more complex projects might take a couple of weeks. The key is communication – a good supplier will give you a realistic timeline upfront and keep you updated. Don't be afraid to ask about their current workload; it makes a big difference.

Finding the Right Partner for Your Project

This might be the most important step. You're not just buying a product; you're buying a service and expertise. Look for a partner who asks a lot of questions about your application. Do they offer feedback on your design to make it more manufacturable or cost-effective?

A great sign is when they proactively discuss your gear's final application and load requirements. This shows they're thinking about the success of your project, not just filling an order. I've found that the back-and-forth communication during the quoting phase is a fantastic indicator of what it will be like to work with them later on.

So, while small-batch CNC gear customization comes with its own set of challenges, the ability to get precisely what you need, when you need it, without a massive inventory commitment, is an incredible advantage for innovators and maintainers alike. 🚀

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C