Key Considerations for Large-Scale CNC Machining: A Practical Guide

Hey there, fellow engineers and procurement specialists! 👋 Have you ever been tasked with sourcing or overseeing a large-scale CNC machining project, only to find yourself sweating over the potential pitfalls? You're not alone. Handling massive workpieces isn't just a scaled-up version of standard machining; it's a whole different ball game where small oversights can lead to huge costs and delays. Let's break down the key things you need to watch out for to ensure your big project runs smoothly.

🛠️ The Big Challenge: Why Size Really Matters

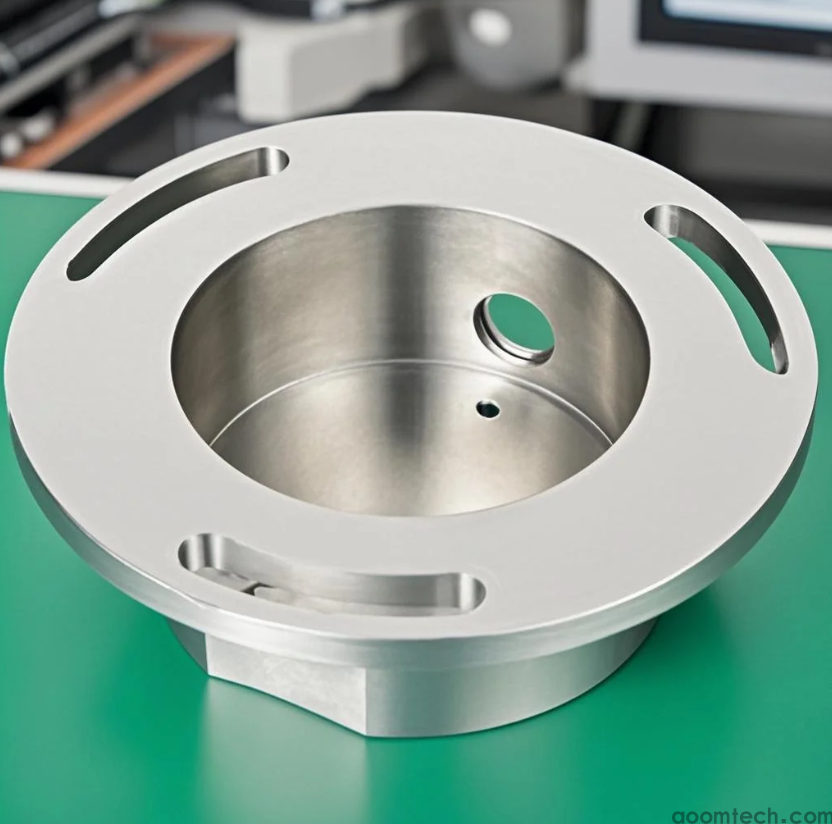

First off, let's talk about the elephant in the room: the sheer size and weight of the parts. This isn't your average desk-sized component. We're talking about parts that might require cranes just to be loaded onto the machine bed. This fundamental difference impacts everything that follows. The machine tool itself needs to be massive enough, with a robust structure to prevent vibrations that can ruin surface finish and accuracy. It's not just about finding a machine with a large envelope; it's about finding one with the backbone to handle the job.

🤔 Machine Selection: It's More Than Just a Big Box

So, how do you pick the right machine? It's tempting to just look for the biggest one you can find, but that's not enough. You need to dig deeper.

Here are a few things I always check:

• Rigidity and Power: The machine's frame must be super stiff. Any flexing under the weight of the part or the force of the cutting tool will directly translate into inaccuracies. A powerful spindle is also non-negotiable for effective material removal on a large scale.

• Table Load Capacity: Don't just look at the travel dimensions. Check how much weight the table can actually support. Exceeding this limit is a recipe for disaster.

• Thermal Stability: Large machines running for long periods generate a lot of heat. The machine's design should manage this heat to prevent expansion that throws off precision over time. The specific mechanisms some manufacturers use to achieve this can be pretty clever, though I must admit, the exact engineering behind the best systems is an area I'm still learning about.

✈️ Precision & Measurement: Keeping it Straight and True

Alright, you've got the part in the machine. Now, how do you keep it accurate over such a large area? This is where things get tricky.

• Achieving Uniform Accuracy: It's one thing for a machine to be precise in one corner. It's another to hold tight tolerances across a two-meter span. This involves the machine's geometric accuracy. You might find that a tolerance of ±.05mm is consistently achievable on a well-maintained large-format machine, but claiming this proves it's the best possible standard would be misleading. It perhaps suggests a well-tuned process, but many other factors are at play.

• In-Process Measurement: For critical dimensions, you can't just machine the part, unload it, and then check it. The part might distort once released. On-site measurement with portable tools is often necessary to make adjustments while the part is still secured.

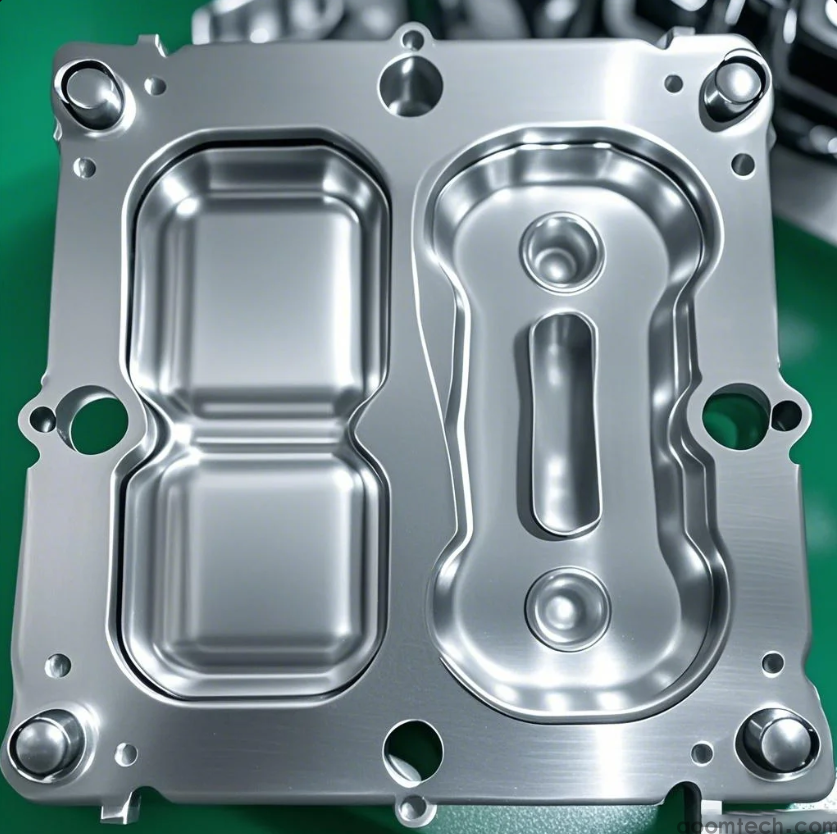

📋 Fixturing & Setup: The Make-or-Break Stage

This is, in my experience, one of the most common points of failure. A flimsy setup on a small part might cause a scrapped component. A poor setup on a large part can cause a catastrophic crash.

My golden rules for setup:

• Secure Clamping: Use enough clamps, and ensure they are positioned to counteract cutting forces without distorting the part. Sometimes, strategic support is even more critical than clamping force itself.

• Avoiding Distortion: Applying too much clamping force can bend a large, thin-walled part. The goal is to hold it firmly, not to twist it into shape. This requires a delicate touch and an understanding of the material's behavior.

• Proper Alignment: Before any cutting begins, you must ensure the part is square and level to the machine's axes. This initial alignment step is boring but absolutely vital. However, it's worth mentioning that even with perfect alignment, material stress relief during machining can sometimes cause movement, which is a nightmare to predict perfectly.

💡 The Human Factor & Planning

Beyond the machine and the part, there's the team. Machining a large part is often a slow process, sometimes taking dozens of hours. Operator skill and vigilance are paramount. A good machinist doesn't just start the program and walk away; they monitor sounds, chips, and conditions, making micro-adjustments as needed. Furthermore, tooling strategy for large parts is different. You need a plan for tool life—changing a worn tool halfway through a 30-hour machining cycle is a complex, time-consuming task that should be anticipated, not reacted to.

From my own observations, projects that include a buffer for unexpected tooling and setup reviews often end up being delivered more reliably. It's that extra bit of planning that separates a smooth operation from a frantic one.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C