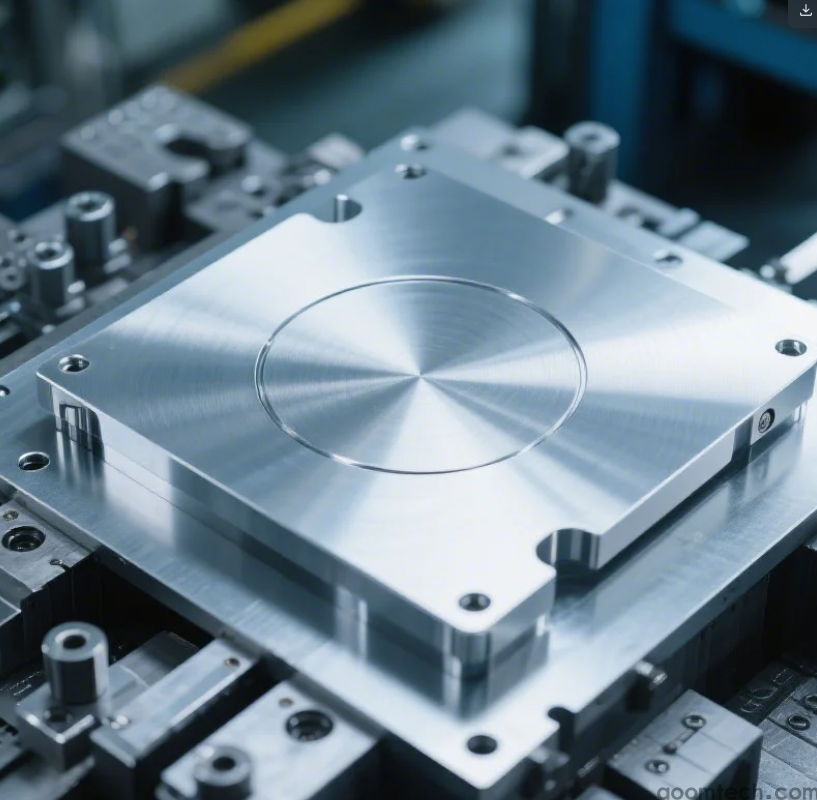

What to Look for in a Large CNC Machining Center for Contract Work?

Struggling to find a reliable partner for your oversized parts? 🤔 You're not alone. Sourcing "Large CNC Machining Center for Contract Work" can be a headache, especially when precision and on-time delivery are on the line. It's not just about finding a machine; it's about finding a capable partner. Let's break down the key things you should be asking.

1. How Big and Powerful is Their Machine, Really?

This seems obvious, but it's the first hurdle. Don't just ask if they have a "large" CNC. Get specific.

Travel Dimensions: What's the maximum part size (X, Y, Z travel) their machine can actually handle? Always provide your own part's dimensions with a little safety margin.

Table Load Capacity: This is a big one for heavy parts. A machine might have the space, but can its table support a 5-ton block of steel? Ask for the maximum weight limit.

Spindle Power: Heavy cuts on tough materials require a powerful spindle. A weak spindle will slow down your job and might even damage the part or the machine. I've seen projects get delayed because this wasn't checked upfront.

2. What About Their Precision and Quality Control?

Big parts are expensive. A small mistake can mean a huge loss. So, how do they ensure accuracy?

Repeatability is Key: It's great if they can hit a tolerance once. But can they do it for every single part in your order? Ask about their machine's repeatability specifications.

In-Process Inspection: Do they just measure the part at the end? The best shops I've worked with check critical dimensions during the machining process. This catches errors early, saving time and material. The specific tools and methods they use, however, can vary a lot from one shop to another.

Documentation: Will they provide inspection reports? This is a sign of a professional outfit that stands behind its work.

3. Can They Handle Your Specific Material?

Not all shops are experienced with all materials. This is a common blind spot for buyers.

Material Experience: Be upfront about what you're machining – is it 304 stainless steel, 6061 aluminum, or maybe something exotic like titanium? Ask if they have proven experience with that specific material. The cutting tools, speeds, and feeds are totally different.

Tooling and Expertise: Machining hardened steel is a world away from machining aluminum. A shop that specializes in one might struggle with the other. Their expertise in material-specific tool paths makes all the difference in the final finish and tooling costs.

4. Don't Forget the "Soft" Skills: Communication and Project Management

You're not just buying a machined part; you're buying a service. This might be the most overlooked part.

Responsiveness: How quickly do they reply to your emails or calls? Slow communication during the quoting phase often predicts slow communication during production.

Project Management: Is there a single point of contact? You don't want to be passed around between sales, engineering, and production. A clear line of communication prevents misunderstandings. From my perspective, a shop with a dedicated project engineer is usually a safer bet.

Problem-Solving Attitude: Things don't always go perfectly. The question is, how do they handle it? A good partner will proactively communicate issues and present solutions, not just problems. This proactive approach is what separates the best from the rest.

Choosing the right contract machining partner is a mix of hard technical facts and softer relationship factors. While the specs of their "Large CNC Machining Center" are the foundation, their communication and problem-solving skills are what will ensure your project's success. Hopefully, this gives you a solid checklist for your next sourcing decision. 👍

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C