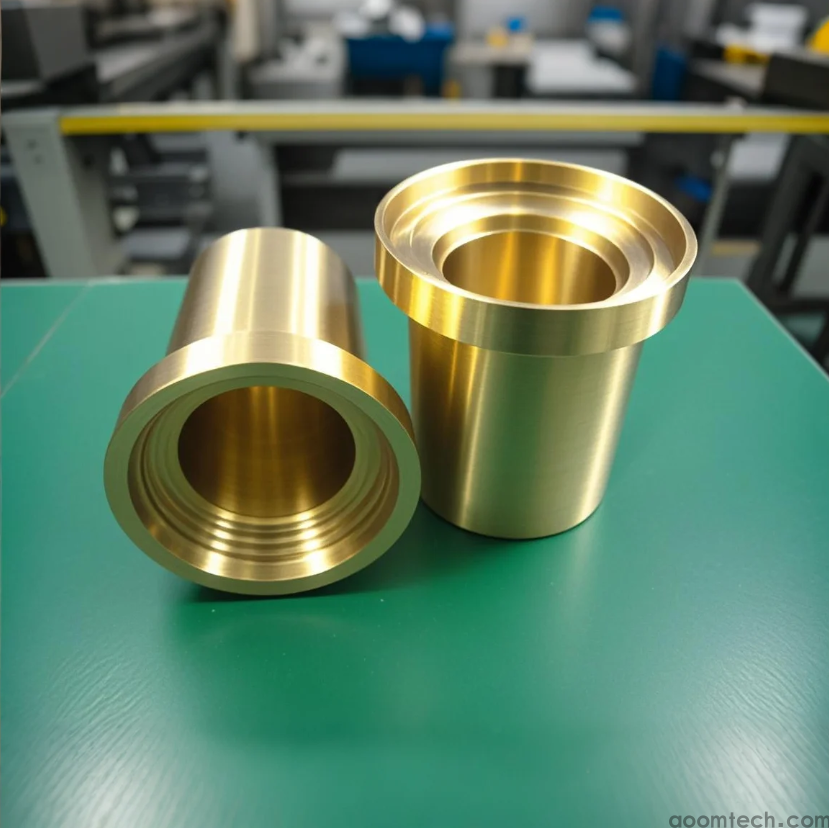

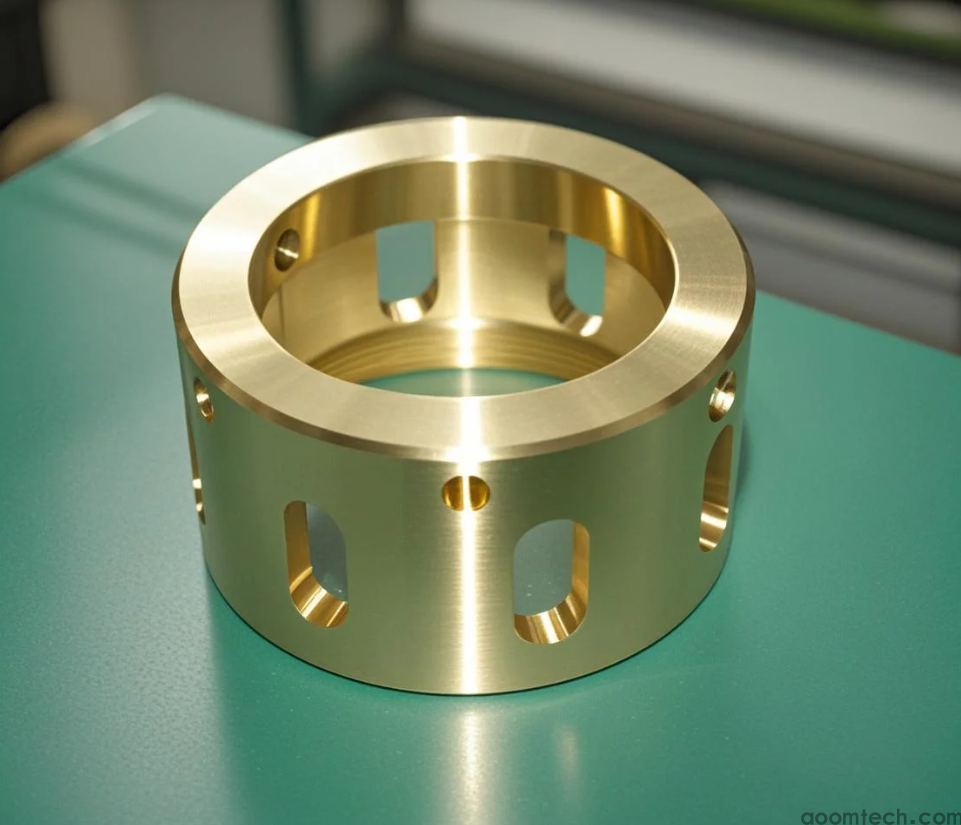

What Tolerance Can You Achieve with CNC Brass Machining? A Practical Guide

Ever sent a CNC brass part design to a machine shop, only to get a call asking to loosen the tolerance—and a higher quote? 😩 You're not alone. Chasing ultra-tight tolerances can skyrocket costs, but how do you know what's actually practical and necessary for your brass component? Let's cut through the confusion and talk real numbers.

So, What's the Realistic Tolerance for CNC Machined Brass?

First off, brass is a dream to machine. It's soft, cuts cleanly, and doesn't wear down tools like some steels. This friendliness gives us a great starting point.

For most standard CNC machining services, a tolerance of ±.025 mm (±.001 inches) is considered good practice and very achievable for brass parts. That's about one-quarter the thickness of a human hair! For many applications, especially in prototypes and general components, this is more than accurate enough.

Now, under ideal conditions—with a modern machine, a skilled operator, and a perfect setup—achieving tolerances as tight as ±.0125 mm (±.0005 inches) on certain features is possible. But here's the catch: this isn't a guarantee for every single dimension on your part. It depends heavily on the part's geometry, feature size, and the machine's capability.

What Factors Can Mess With Your Machining Precision?

Thinking you'll get that ±.0005" across the board? Hold that thought. Several things can throw a wrench in the works.

• The Machine's Health & Calibration: An older or poorly maintained CNC machine simply won't hold the same precision as a top-tier one. It's the difference between a family sedan and a Formula 1 car.

• Tool Wear & Vibration: As the cutting tool wears down, ever so slightly, the cuts become less precise. Vibration during machining can also lead to inaccuracies, though brass is pretty good at damping that.

• Part Geometry & Feature Size: This is a big one. It's easier to hold a tight tolerance on a large, stable surface than on a tiny, delicate pin or a deep, narrow hole. The mechanics of cutting get trickier. The specific mechanism of how thin walls vibrate during machining is something we're still trying to perfectly model for every scenario.

• Temperature Fluctuations: While brass has good thermal stability, the machine itself and the environment can expand or contract with temperature changes, impacting measurements. It's usually a minor factor, but it adds up when you're chasing microns.

How to Get the Best Precision Without Breaking the Bank?

So, you want the best possible part without paying a "precision premium" for no reason? Here's what I always recommend to my clients.

1. Only Be Critical Where It Counts: Don't call out a super tight tolerance on the entire drawing. Identify the critical features—like a mating surface or a press-fit hole—and specify the tight tolerance only there. Leave non-critical dimensions with a standard, looser tolerance. This saves a ton of money.

2. Talk to Your Machinist Early: Seriously, just have a conversation. Send them your design and ask, "What's achievable here, and what will cost me?" A good machinist will tell you if a design is needlessly expensive to produce. This collaboration is gold.

3. Consider the Post-Processing: Sometimes, it's more cost-effective to machine a part to a standard tolerance and then use a secondary process like grinding or honing to achieve a super-fine finish on just one specific area.

My Take: Is "Tighter" Always "Better"?

In my experience, the obsession with ever-tighter tolerances is often misplaced. I've seen projects burn through budgets for gains that provided zero functional benefit. The real goal isn't the smallest number possible; it's the right number for your part to work reliably in its intended application.

Chasing the last micron might prove your machine shop's mettle, but it doesn't always make your product better. In fact, an overly tight tolerance might make the part more sensitive to wear and environmental changes. Sometimes, a little bit of "slop" is what makes a design robust and durable. But, for a component in a high-speed mechanism or a instrument, that last micron is everything. It always comes down to the application.

Ultimately, achieving high precision in CNC brass machining is less about pushing a machine to its absolute limit and more about smart design, clear communication, and understanding the trade-offs. Knowing what's practically possible lets you design with confidence and source parts effectively. 🚀

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C