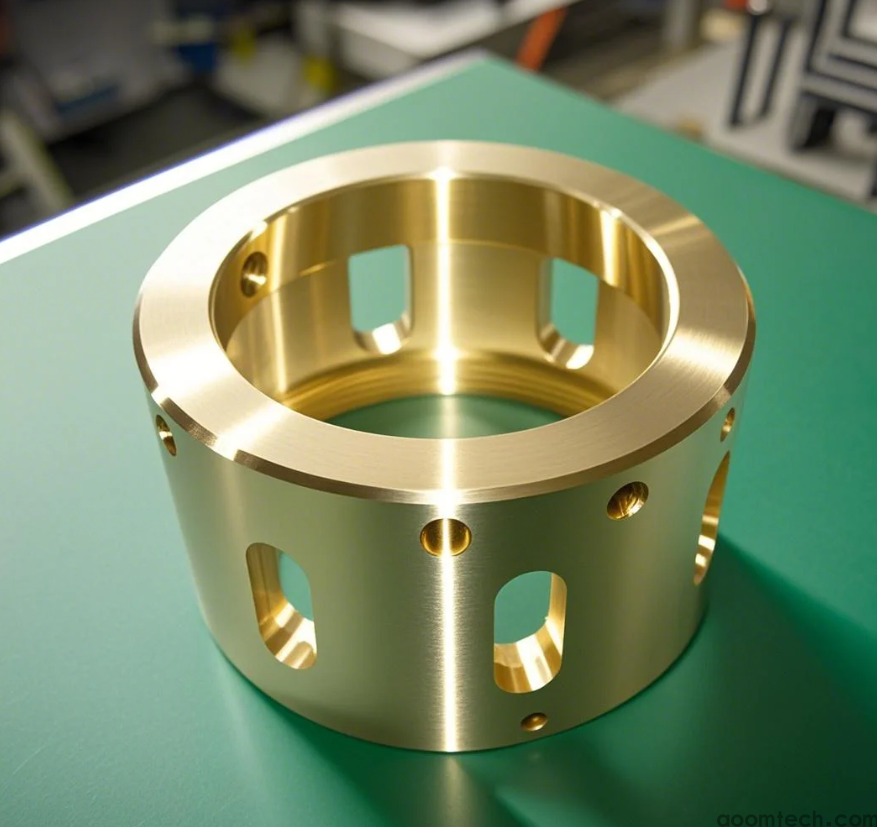

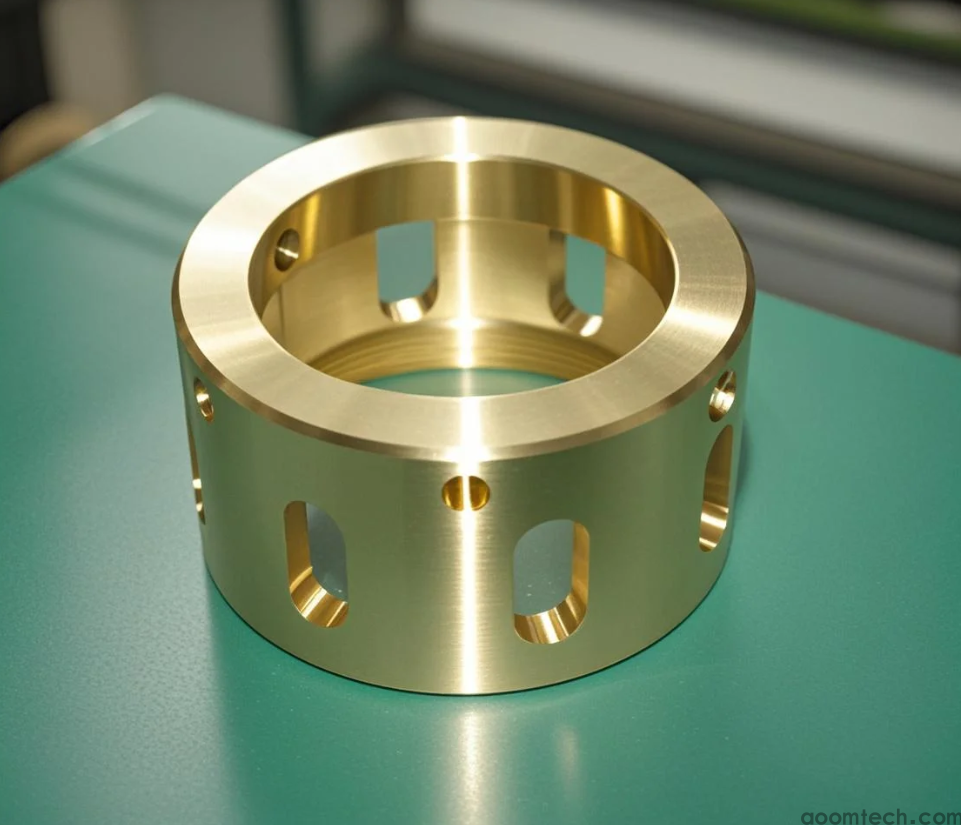

Precision CNC Machining for Large Copper Parts: A Comprehensive Guide

Hey there, fellow engineers and procurement pros! 👋 Are you tired of the endless headaches that come with sourcing or overseeing the production of large, precision copper components? You know the ones – where a tiny deviation spells disaster, or the surface finish just isn't up to par? You're not alone. Getting it right with big copper parts is a whole different ball game compared to smaller stuff or other materials. So, what's the real deal with large copper part precision machining? Let's dive in and break it down, question by question.

What Makes Machining Large Copper Parts So Tricky?

Well, it's not like machining a small brass gear. First off, copper is super soft and gummy. When you're taking deep cuts on a massive block, the heat builds up fast. This heat can make the tool wear out quicker and might even cause the copper to stick to the tool. Imagine trying to carve a detailed sculpture out of a giant stick of butter – that's kind of the challenge, but with heat and pressure. Plus, because the parts are large, any internal stress in the material can lead to warping after machining, which is a nightmare for holding tight tolerances.

What Are the "Must-Have" Features in a CNC Machine for This Job?

You can't just use any old machine. For large copper pieces, you need a CNC setup that's built for the task.

➤ Rigidity is King: The machine frame has to be super sturdy to handle the weight and the cutting forces without shaking. Any vibration will show up on your surface finish.

➤ Power and Torque: Spinning a large chunk of metal and cutting it requires a powerful spindle that won't bog down.

➤ Advanced Cooling Systems: This is non-negotiable. A great coolant system is vital to manage that pesky heat we talked about and to wash away the long, stringy chips that copper loves to produce.

I've seen setups where they use mist coolant or even high-pressure through-tool coolant, and it makes a world of difference. The exact best setup, though, can depend on the specific copper alloy you're using – something we're still figuring out the perfect formula for in some cases.

How Do You Actually Achieve "Precision" on a Big Scale?

Ah, the million-dollar question. It's all about a combination of things.

➤ Toolpath Strategy: It's not just about hacking away. Using smarter toolpaths that distribute heat and force evenly is crucial. Think trochoidal milling or adaptive clearing.

➤ Tool Selection: Using sharp, positive-rake tools designed for non-ferrous metals helps reduce cutting force and heat. Sometimes, diamond-coated tools are used for an insane tool life, but they're a bigger upfront investment.

➤ Fixturing: How you hold the part is half the battle. You need custom fixtures that secure the part firmly but without causing distortion. I often use modular vises and strategic clamping. It's a bit of an art form, to be honest.

That being said, even with the best plans, holding a tolerance of ±.01mm across a 500mm part is incredibly challenging. It might suggest that environmental factors like shop floor temperature swings play a bigger role than we sometimes account for.

What About the All-Important Surface Finish?

This is where you can really see the quality. Copper is often chosen for its conductivity or its appearance, so a scratched or rough surface is a no-go.

Avoiding scratches from those stringy chips is job one. Good chip and coolant flow is the secret. Sometimes, we'll use a final pass with a very light cut and a high speed to get that mirror-like sheen. It's time-consuming, but oh, so worth it for the final product.

My Personal Take: Don't Underestimate the Human Factor

After years in this field, here's my two cents. While the machine and tools are critical, the experience of the programmer and operator is what ties it all together. Someone who knows how to "listen" to the machine, who can spot a chip color change that indicates too much heat, and who can tweak speeds and feeds on the fly – that's priceless. This deep, practical knowledge is something that's built over countless hours on the shop floor, and it's not something you can fully capture in a manual. On the other hand, modern CNC controls with adaptive machining are getting scarily good at automating this intuition.

Alright, that's a wrap from me. I hope this deep dive gives you a clearer picture and maybe even a few ideas for your next big copper project. Remember, it's a mix of the right tech, the right techniques, and a healthy dose of hands-on experience. 🛠️

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C