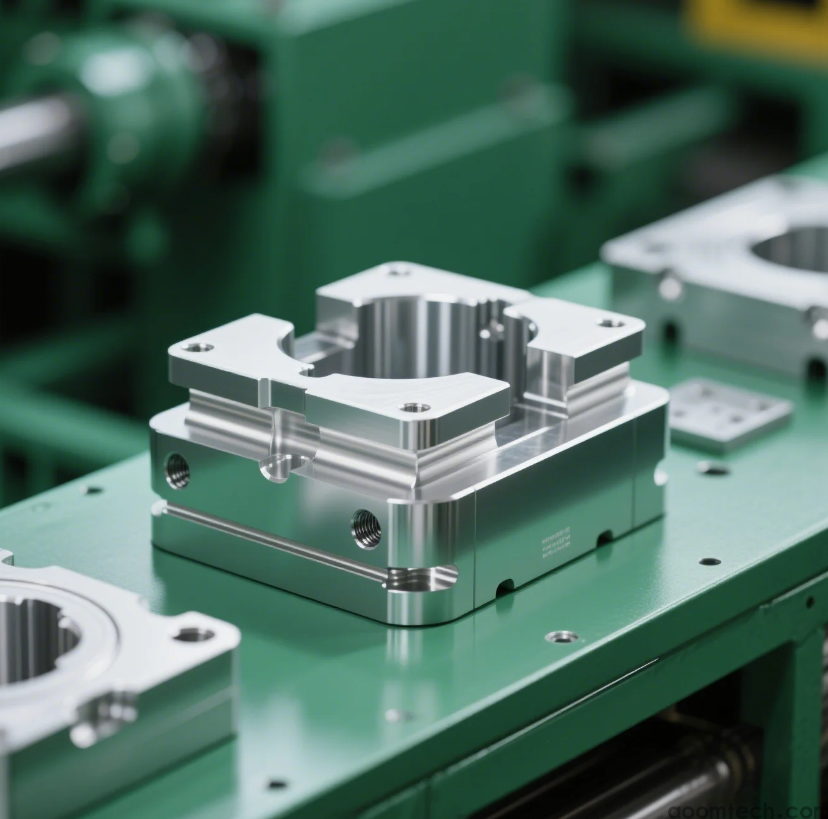

CNC 3-Axis Product Machining

What Is CNC 3-Axis Machining?

CNC 3-axis product machining refers to the subtractive manufacturing process where a computer-controlled machine tool operates along three linear axes (X, Y, and Z) to create precision parts. This method is widely used for prototyping and mass production of components with moderate complexity, such as flat surfaces, pockets, and simple contours. AOOM Technology specializes in delivering high-accuracy 3-axis CNC machining services for industries like aerospace, automotive, and electronics.

Key Advantages of 3-Axis CNC Machining

1. Cost-Effectiveness: Ideal for projects with budget constraints due to lower setup and operational costs compared to multi-axis systems.

2. Fast Turnaround: Simplified programming and tool paths reduce production time for standard geometries.

3. Material Versatility: Compatible with metals (aluminum, steel), plastics, and composites.

AOOM's Expertise in 3-Axis CNC Solutions

At AOOM, we combine advanced CNC 3-axis machining equipment with ISO 9001-certified processes to ensure dimensional accuracy (±.01mm) and surface finishes up to Ra .8μm. Our engineers optimize tool selection and cutting parameters to minimize waste and maximize efficiency. Visit aoomtech.com to explore our case studies or request a free project review.

Applications Across Industries

• Automotive: Brackets, housings, and sensor mounts.

• Medical: Surgical instrument components.

• Consumer Electronics: Enclosures and heat sinks.

Why Choose AOOM for Your Project?

With 15+ years of CNC manufacturing experience, AOOM provides end-to-end support—from DFM analysis to post-processing (anodizing, powder coating). Our transparent pricing and 24/7 customer service ensure a seamless partnership for your 3-axis machining needs.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C