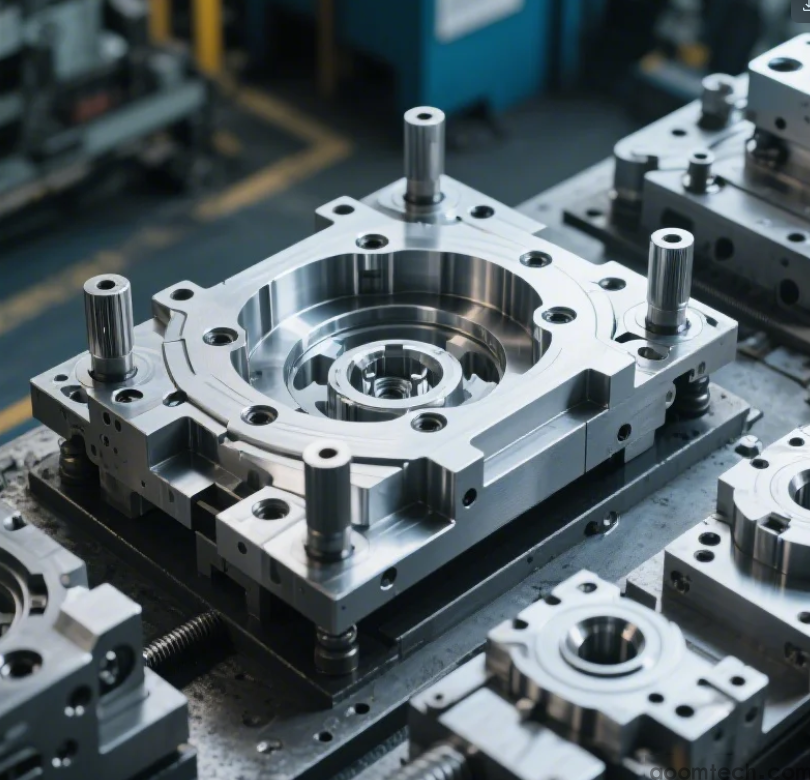

CNC Automotive Mold Processing Technology

In modern automotive manufacturing, CNC automotive mold processing technology plays a pivotal role in producing high-precision components with exceptional consistency. As a leading CNC machining service provider, AOOM Technology specializes in delivering cutting-edge solutions for automotive mold manufacturing.

The Importance of Precision in Automotive Mold Manufacturing

Automotive molds require extreme precision as they directly impact the quality of final vehicle components. Our CNC machining processes ensure dimensional accuracy within ±.01mm, meeting the stringent requirements of automotive OEMs and Tier 1 suppliers.

Key Processes in CNC Automotive Mold Manufacturing

Our comprehensive approach includes:

3D modeling and simulation

High-speed milling of mold cavities

EDM (Electrical Discharge Machining) for complex geometries

Precision grinding for final surface finishing

Material Selection for Automotive Molds

We work with various mold-grade materials including P20, H13, and S7 tool steels, as well as aluminum alloys for prototype molds. Each material undergoes rigorous testing to ensure it meets automotive industry standards for durability and performance.

Quality Assurance Measures

AOOM Technology implements a strict quality control system featuring:

CMM (Coordinate Measuring Machine) inspection

Surface roughness testing

Hardness verification

Comprehensive documentation for traceability

Our expertise in automotive mold processing enables us to deliver molds with superior surface finish, extended service life, and optimal production efficiency. With state-of-the-art CNC equipment and a team of skilled technicians, AOOM Technology stands ready to be your trusted partner for automotive mold solutions.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C