CNC Mold Processing Price Guide

As a leading CNC machining service provider, AOOM Technology understands that cost is a critical factor when sourcing precision mold components. This guide breaks down the key elements influencing CNC mold processing prices to help you make informed procurement decisions.

Factors Determining CNC Mold Processing Costs

1. Material Selection: Aluminum molds typically cost 30-50% less than hardened steel due to faster machining times.

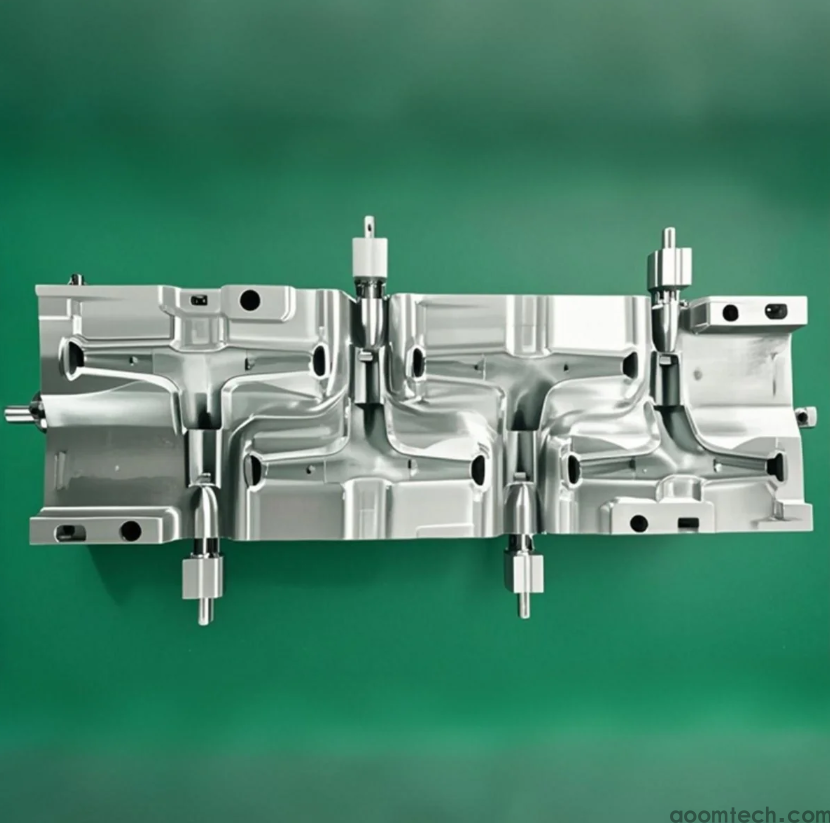

2. Complexity: Multi-cavity molds with undercuts or thin walls require specialized tooling, increasing costs by 20-40%.

3. Tolerances: Tight tolerances below ±.01mm may double machining time versus standard ±.05mm requirements.

AOOM's Competitive Advantages

Our CNC mold manufacturing services offer:

• 15% cost reduction through optimized tool paths using Mastercam software

• 3-axis/5-axis machining centers capable of ±.005mm repeatability

• ISO 9001-certified quality control with full material traceability

Transparent Pricing Structure

Sample price ranges for common mold components:

• Small aluminum injection molds: $800-$2,500

• Medium steel stamping dies: $3,000-$8,000

• Complex multi-slide molds: $15,000+

For accurate quotations, provide technical drawings including material specifications, surface finish requirements (Ra), and annual production volume. Our engineers will recommend the most cost-effective manufacturing strategy without compromising quality.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C