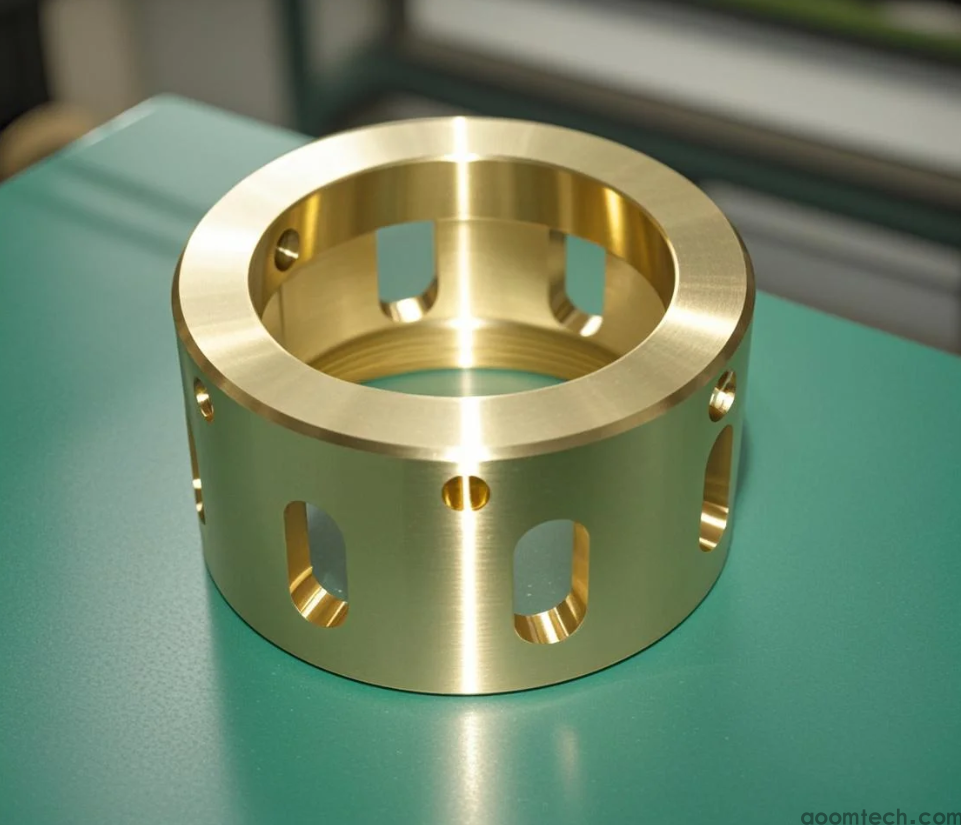

CNC Copper Machining Process Flow

As a professional CNC copper machining service provider, AOOM Technology specializes in delivering precision-engineered copper components for industries ranging from electronics to aerospace. This article will break down the critical steps of our proven process flow, ensuring optimal quality and efficiency for your projects.

1. Material Selection and Preparation

The CNC copper machining process begins with selecting the appropriate copper alloy (C10100, C11000, etc.) based on conductivity, hardness, and corrosion resistance requirements. At AOOM, we perform ultrasonic cleaning and stress-relief annealing to ensure material stability before machining.

2. Precision CNC Programming

Our engineers utilize advanced CAM software to create optimized toolpaths, accounting for copper's unique properties like high thermal conductivity and gummy cutting characteristics. This stage includes:

Tool selection (diamond-coated end mills preferred)

Coolant strategy development

Chip evacuation planning

3. Machining Execution

The actual CNC machining process involves:

High-speed milling with RPM adjustments for heat management

Continuous coolant application to prevent work hardening

In-process quality checks using CMM equipment

4. Post-Processing and Quality Control

After machining, components undergo:

Deburring and edge finishing

Surface treatments (electropolishing, passivation)

Final inspection with 3D scanning and conductivity testing

AOOM Technology's ISO 9001-certified facility guarantees consistent results for your copper machining needs. Our CNC copper machining capabilities include complex geometries with ±.005mm tolerances, making us the preferred partner for critical applications.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C