Which CNC Machining Company to Choose? An Analysis of the 5 Core Capabilities for Custom Part Machining

In today’s rapidly developing manufacturing industry, many enterprises face a common pain point: how to find a truly reliable CNC machining company? This problem becomes even more prominent when dealing with non-standard, irregular-shaped, or high-precision-required parts. The ability to machine custom parts has become an important criterion for measuring the technical strength of a CNC enterprise.

🔧 What Is Custom Part CNC Machining?

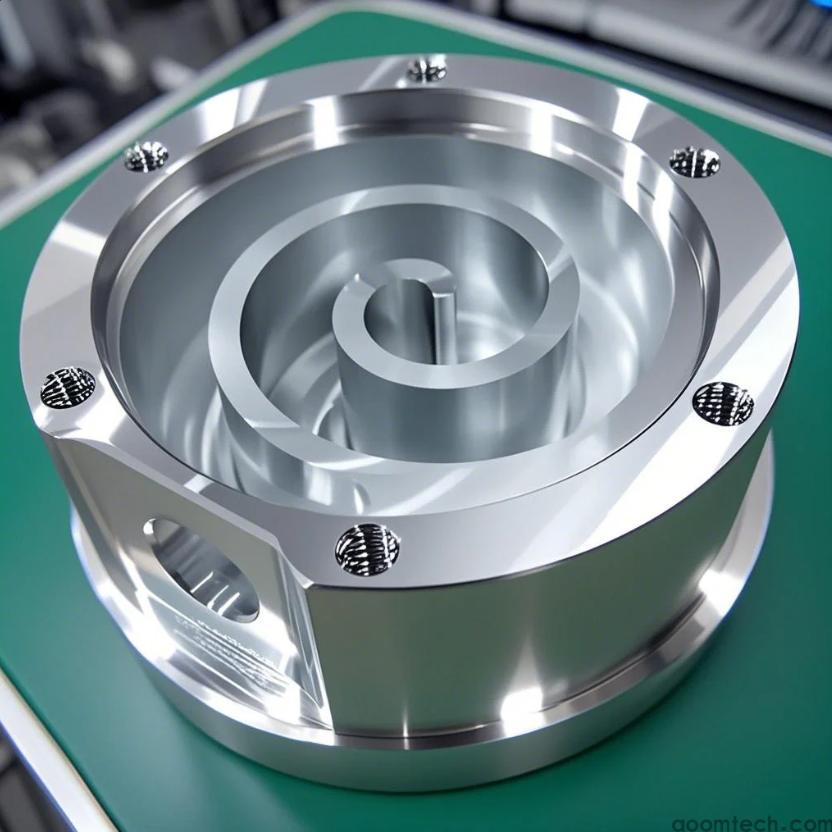

Custom part CNC machining refers to the numerical control machining of metal or plastic parts that are non-standard in specifications and custom-designed. Such parts usually cannot be mass-produced through standard processes; instead, they require personalized programming and machining based on drawings or specific requirements provided by customers. Common custom parts include:

- Connecting parts with special structures

- Housings with irregular cavities

- Transmission components requiring high precision

- Functional prototypes for small-batch trial production

⚙️ The 5 Core Capabilities of a High-Quality CNC Machining Company

1. Precision Machining Technology Strength

It can meet high-precision requirements of ±0.001mm and is equipped with advanced machining capabilities such as 5-axis simultaneous machining and turn-mill composite machining. This not only requires advanced CNC equipment but also experienced programmers and operators.

2. Multi-Material Processing Capability

It can provide corresponding machining solutions for materials ranging from common aluminum alloys and stainless steels to engineering plastics and special alloys (such as PEEK and titanium alloys). Differences in material properties directly affect tool selection, cutting parameters, and cooling methods.

3. Strict Quality Control System

It is equipped with testing equipment such as coordinate measuring machines (CMM), optical image measuring instruments, and surface roughness testers. This ensures that every link—from raw material warehousing to finished product delivery—is traceable, realizing full-process quality tracking.

4. Flexible Production Scheduling and Delivery Control

Custom parts often have urgent needs. The ability to respond quickly, arrange production flexibly, and strictly adhere to delivery schedules reflects an enterprise’s project management capabilities.

5. Industry Application Experience and Solution Capability

Enterprises deeply engaged in specific industries (such as automotive, medical, aerospace, and electronic products) better understand the industry’s unique standards, precision, and material requirements. They can provide more reliable solutions rather than just simple “machining according to drawings.”

🤔 How to Choose a Cooperative Company?

When selecting a CNC machining company, it is recommended to consider the following aspects:

- Case Review: Ask the supplier to provide past machining cases of similar products, especially real-shot videos or pictures of complex custom parts.

- Equipment List: Understand the brand, model, quantity, and machining range of the company’s main machining equipment.

- Quality Inspection Reports: Check quality inspection reports from other customers to evaluate its quality control level.

- Communication Efficiency: Gauge its technical response speed and service awareness through preliminary communication.

For many startups or R&D teams, small-batch custom part machining needs are often difficult to get a quick response from large-scale processing plants. At this time, medium-sized enterprises focusing on non-standard and small-to-medium-batch machining show their advantages in flexibility. They are usually more willing to take on complex, small-batch orders and provide more cost-effective services.

It is worth noting that custom machining does not mean blindly pursuing “high precision and advanced technology.” The most suitable option is the best one. The key lies in whether the CNC enterprise can accurately understand the product’s functional requirements and, on the premise of ensuring performance, recommend the most economically reasonable machining process and materials.

In the future, with the growth of personalized demand in the manufacturing industry, the ability to machine custom parts will become increasingly important. Choosing a CNC machining company with the above core capabilities will be a key link in the success of a product.

Do you need me to optimize the translation for specific scenarios, such as making it more concise for a company promotional leaflet or more technical for communication with overseas engineering teams? I can also add annotations for industry-specific terms (like PEEK) to ensure accurate understanding.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C