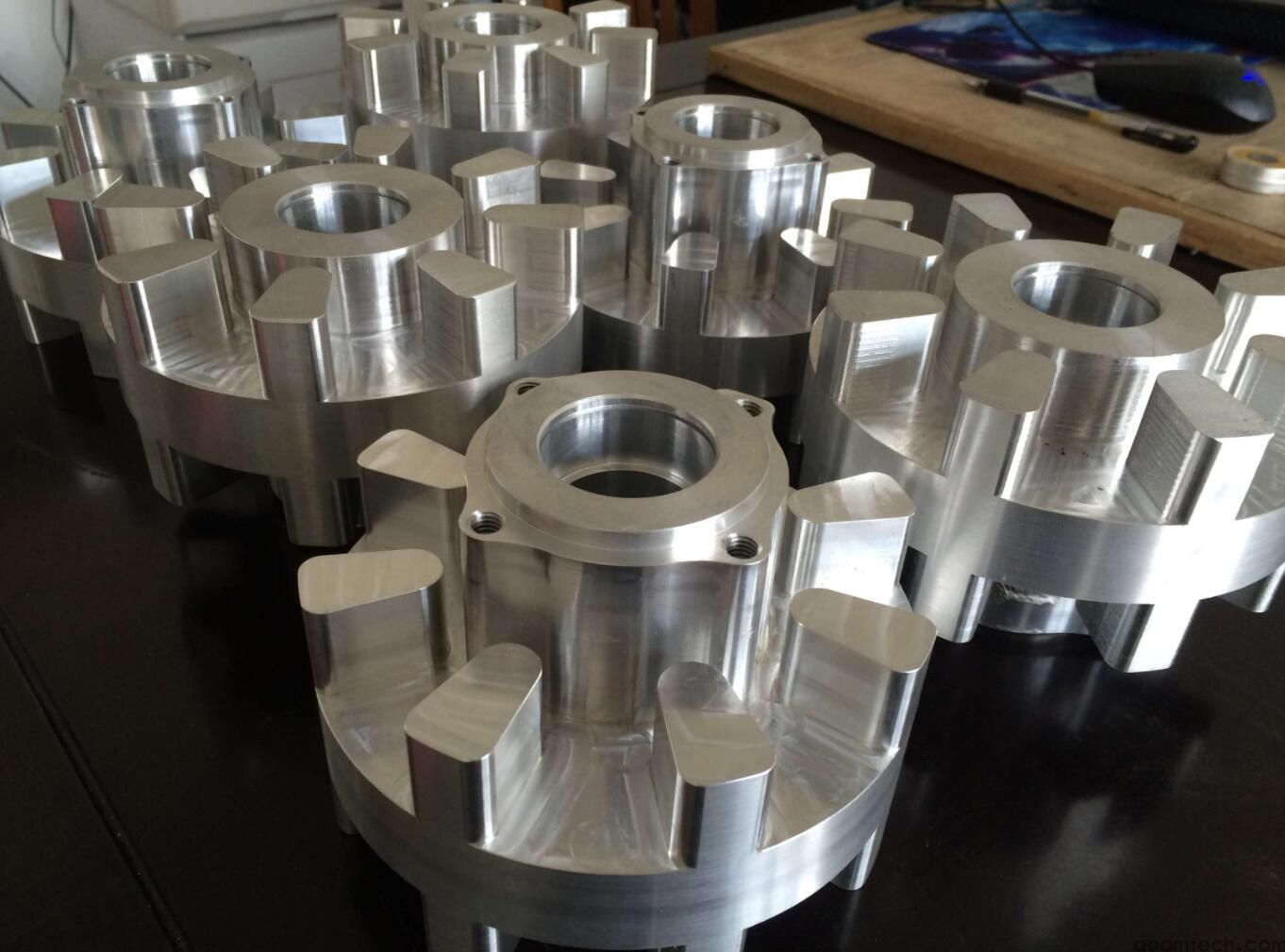

CNC Machining Precision Control Methods & Custom Part CNC Machining Process

I’ve noticed that many friends new to the industry get overwhelmed at the mention of CNC machining for parts 😵, always thinking it’s incredibly complicated! But actually, as long as you grasp the core logic, even beginners can get the hang of it quickly. Today, we’ll break down two key points: precision control and the custom part machining process. After reading this, you’ll definitely stop feeling confused!

🤔 Why Does Precision Always Go Out of Control?

First, let’s address a common pain point—have you often encountered issues like large dimensional deviations or surfaces as rough as sandpaper? Don’t panic! This is mostly caused by three main reasons:

1. Wrong Tool Selection: For example, using a regular steel cutter on titanium alloy will lead to edge chipping in no time! I suggest using double-edged end mills for aluminum parts and prioritizing cobalt-based coated cutters for stainless steel—this can double the tool life 📈.

2. Random Parameter Settings: Cutting speed and feed rate aren’t numbers you can just guess! ⏱️ For instance, the recommended spindle speed for aluminum alloy is 8,000–12,000 rpm, while for steel, it needs to be reduced to 2,000–5,000 rpm. Otherwise, you’ll either burn the tool or end up with terrible efficiency.

3. Uncalibrated Machine Tools: Regularly checking pitch errors with a laser interferometer is a must—you can’t skip this! One factory skipped this inspection for half a year, and its repeat positioning accuracy went from ±0.003mm to ±0.02mm, with the scrap rate jumping by 15% directly 😱.

🔧 Custom Part Machining Process (with Pitfall-Avoidance Guide)

The most frustrating thing about custom parts is that “every project requires a different plan,” but the core process actually follows a set pattern! I usually use this workflow:

STEP 1: Drawing Analysis → Focus on tolerance markings! A colleague once missed a ±0.05mm hole position标注, leading to mass rework and a 60,000-yuan loss 💰.

STEP 2: Process Design → This is where people often mess up! 👉 For thin-walled parts, you must use “rough machining first, then finish machining” with layered milling. Otherwise, the deformation will be so bad you won’t even recognize the part!

STEP 3: Programming & Simulation → Don’t skip collision detection in CAM software! Last year, I saw a disaster where the tool collided with the fixture—repairing the spindle cost over 8,000 yuan 💸.

STEP 4: First Part Trial Cutting → Full inspection with a coordinate measuring machine (CMM) is a must! I once detected dimensional deviations caused by thermal expansion (when the workshop temperature difference exceeded 5°C), and adding coolant solved the problem immediately ✅.

STEP 5: Mass Production → It’s recommended to spot-check 1 part every 50 pieces to monitor tool wear in real time.

🚀 Exclusive Practical Data

Forget all the theories—here’s some real-world data I dug up:

- By using dynamic tool path compensation technology, one enterprise stabilized the machining precision of titanium alloy parts within ±0.01mm, increasing the yield rate by 23% 🎯.

- A flexible fixture system reduced changeover time from 40 minutes to 5 minutes, making it especially suitable for small-batch custom orders (like batches of around 100 pieces)!

- I’m sharing a snippet of my “cutting parameter table” (see partial screenshot below)—message me if you want the full version!

| Material | Recommended Spindle Speed (rpm) | Feed Rate (mm/min) | Depth of Cut (mm) |

|----------------|----------------------------------|--------------------|--------------------|

| Aluminum Alloy 6061 | 10,000–15,000 | 2,000–4,000 | 0.3–0.6 |

| Stainless Steel 304 | 2,000–3,500 | 500–800 | 0.1–0.3 |

| Titanium Alloy TC4 | 1,000–2,000 | 200–500 | 0.05–0.15 |

💡 My Final Thoughts

Let me end with some honest advice—when it comes to precision control, equipment only accounts for 30%; the remaining 70% depends on process management! I’ve seen too many factories splurge on 5-axis machines but fail because of poor basic management 😮💨.

For beginners, remember: Focusing on tool parameters and machine maintenance first is much more practical than chasing high-end equipment! Also, here’s a little-known fact—a 1°C fluctuation in workshop temperature can cause a 0.001mm deviation in the dimensions of carbon steel parts 🌡️. So, let the machine warm up for 15 minutes before working on hot summer days—you’ll feel the difference once you try it!

Do you need me to adjust the translation style, such as making it more technical for engineering documents or more casual for a beginner training guide? I can also add annotations for professional terms (like “CAM software”) to help non-technical readers understand better.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C